数控机床行业发展现状分析

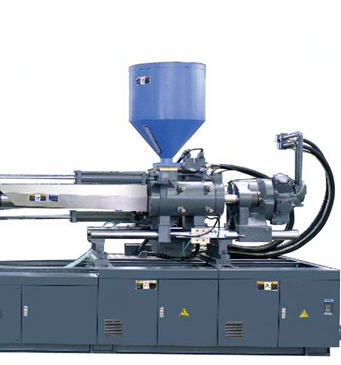

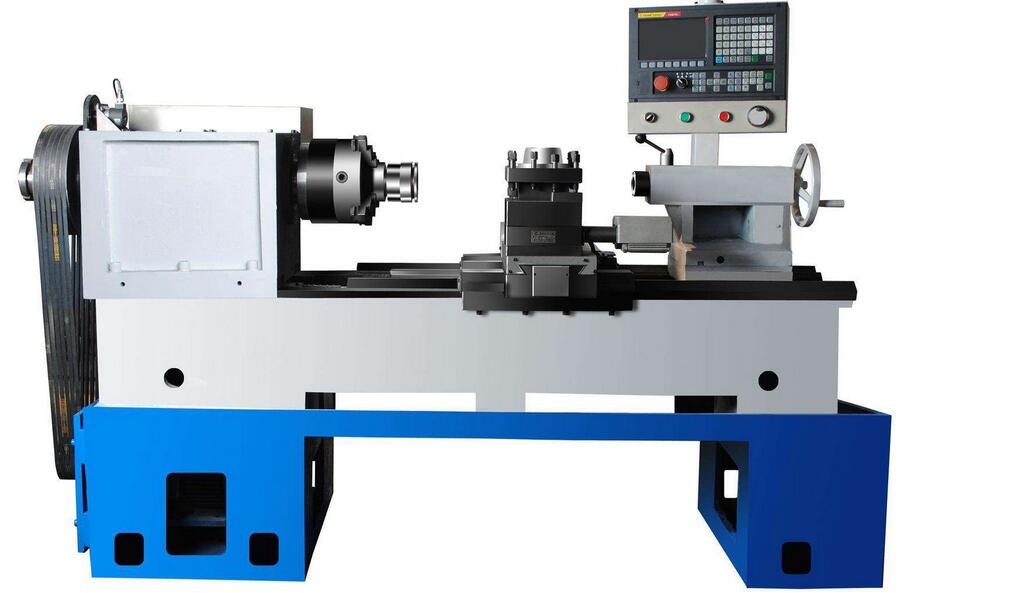

机床作为“工业之母”,是一个国家制造业水平高低的象征。数控机床是由美国发明家约翰·帕森斯上个世纪发明的。随着电子信息技术的发展,世界机床业已进入了以数字化制造技术为核心的机电一体化时代,其中数控机床就是代表产品之一。数控机床是一种高效能的,装有程序控制系统的自动化机床,能较好地解决复杂、精密、小批量、多品种的零件加工问题,代表着现代机床控制技术的发展方向。

The industrialized countries such as Europe, the United States and Japan have successively completed the industrialization process of CNC machine tools, and China started from the 1980s and is now in the development stage. Although China's foundry machine tool industry has achieved certain results, it still faces many constraints. Compared with foreign products, the gap between China's CNC machine tools is mainly in the high-speed, high-efficiency and precision of machine tools.

The CNC machine tool industry is growing rapidly

From the perspective of China's CNC machine tool market, benefiting from the rapid development of China's automotive, aerospace, shipbuilding, power equipment, engineering machinery and other industries, the machine tool market, especially CNC machine tools, has generated huge demand, and the CNC machine tool industry has grown rapidly. According to the statistics of China's CNC machine tool industry market demand forecasting and investment strategic planning analysis report released by Prospective Industry Research Institute, the sales revenue of CNC machine tools in China exceeded RMB 240 billion in 2014-2016, and the sales of CNC machine tools in China in 2016 were 273.23 billion yuan, an increase of 7.69%. As of 2017, the sales of CNC machine tools in China was about 300.3 billion yuan, exceeding 300 billion yuan for the first time.

In 2010, the output of CNC machine tools in China was 236,000 units. In 2011, the output of CNC machine tools in China increased to 272,100 units. In 2013, the output of CNC machine tools in China dropped to 225,700 units. In 2014, the output of CNC machine tools in China exceeded 300,000 units. By 2016, the output of CNC machine tools in China reached 318,000 units. By 2017, the output of CNC machine tools in China reached 301,000 units.

Downstream applications are still dominated by the automotive industry, and consumer electronics will become the mainstream application market in the future.

From the perspective of the downstream consumption demand of the CNC machine tool industry, the automobile is the main downstream demand field, with the consumption ratio accounting for about 42%; the second is the aerospace, the consumption proportion is about 18%; the mold and engineering machinery are the CNC machine third and The fourth consumer sector accounts for around 15% and 10% respectively.

In the future, with the gradual popularization of smartphones, the speed of updating and upgrading, the promotion and development of 3C industry terminal equipment such as consumer electronics and communications such as tablet PCs and wearable devices, the 3C industry will usher in the spring of development, the consumer electronics industry. The product will become a new growth point in the industry and will strongly promote the development of light-duty CNC machine tools used in this field.

Analysis of the Three Development Trends of China's CNC Machine Tool Industry

The economic development of the 13th Five-Year Plan focuses on the transformation of economic growth mode. Advanced manufacturing is the transformation direction of traditional manufacturing. The development of high-tech industries such as electronic information, bioengineering, new energy and new materials will be precise and efficient. Special CNC machine tools have opened up new demands;

From the analysis of geographical development, the upgrading of industries in eastern China, the revitalization of old industrial bases in the Northeast and the development of the central and western regions, and the pace of providing a domestic market for the development of CNC machine tools industry; economic globalization, transfer of international capital and industry to China, international technology The exchange of talents and the strong development of China's international trade have provided an external environment for the development of China's CNC machine tool industry, making the CNC machine tool industry a rare strategic development period. In the future, China's CNC machine tool industry will mainly present the following three major development trends:

1. The comprehensive competitiveness of domestic CNC machine tools will be greatly improved, which will cause a fundamental change in the market share of domestic CNC machine tools.

2. A wholly-owned enterprise or joint venture established by a group of multinational machine tool groups in China, such as Germany's DMG, American Harding, Japan's Little Giant, etc., localized production will form production capacity.

3. The industrialization of popular CNC machine tools will be formed. Universal CNC machine tools and machining centers CNC machine tools are among the fastest growing and the largest proportion of all kinds of products, and they are also the most widely used equipment in the manufacturing industry. As a mid-range CNC machine tool, the popular CNC machine tool has become the mainstream of consumption. Its proportion in CNC machine tools has exceeded 30%, and the growth rate is much higher than other types of machine tools, including the growth rate of CNC machine tools.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite