With the implementation of China's double-point policy and the ban on the sale of pure fuel vehicles in various countries around the world, major OEMs have taken the development of new energy vehicles as a crucial part of the follow-up development strategy, which has also created the current martial art. Lin Li's new energy system program, the technical routes can be described as the Eight Immortals across the sea. For the Chinese market, it can be said that it is inclusive, and draws on the strengths of the family. Before the small series, the article “In the face of increasingly strict fuel consumption standards, where does new energy go?” From the aspect of hybrid vehicle configuration, it compares and analyzes the current market. The mainstream topology solution, if you want to decide to win the battle of Huashan, you can't have a watch, and you need to pay attention to the internal power, that is, the study of the electric drive system solution.

As the saying goes, the layman looks at the excitement, the insider looks at the doorway, faces the guidance and promotion of the policy, faces the new trend and new market demand, and wants to stand out from the competition, the development of the new energy vehicle electric drive system can be described as a challenge.

The first challenge is the impact of the “new four”

The rapid development of automation, interconnection and sharing has led to the continuous advancement and rapid development of big data analysis, cloud interconnection, full lifecycle maintenance, and automatic driving, which in turn require higher functional safety levels for electric drive systems. Having a correspondingly redundant design will also lead to the development of new technologies such as wireless charging.

The second challenge is "complete vehicle technology innovation"

With the development of electrification, high reliability, high efficiency, multi-platform application and low cost will be an important assessment point in the integrated design of the whole vehicle, which will also require a more compact structure design and more Excellent performance output and lower system power consumption.

The third challenge comes from “the development of the vehicle electrical and electronic architecture”

From distributed controllers to domain controllers to central integrated controllers and even cloud interconnects, the transformation of electronic and electrical architectures will make higher requirements for integration, communication, and software standardization of electric drive systems. Not only will the integration of components be brought about, the integration and integration of functions will be an important development in the future, and the software design standardization and portability issues brought by integration will make the software architecture based on Autosar an important one. Research points, and in the communication mode, the larger and more convenient data transfer will make Flex Ray, Ethernet and so on.

Then, how to deal with many challenges, if you want to win the competition, how should you deal with each other?

Personally think: First of all, nature needs to grasp the development trend and lay a solid foundation. Whether it is for hybrid or pure electric vehicles, it is especially important to choose the technical route that suits you in the current situation of struggling.

For hybrid systems

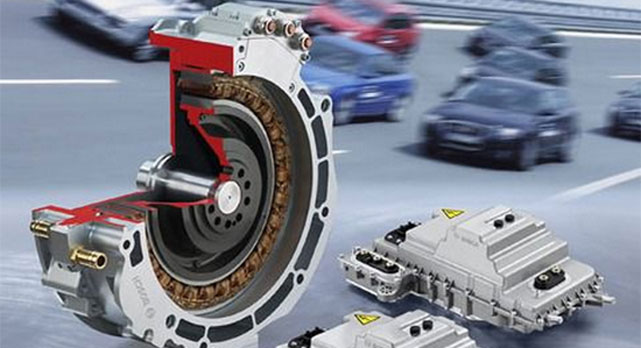

For companies with considerable gearbox mechanical R&D design experience, consider the form of deep integration of the motor and reducer (eg eDCT, eAMT, P2);

For a new generation of vehicles in the field of hybrids or a vehicle with more experience in engine matching, if the design of the reducer and the reasonable matching of the engine can be solved, the series and parallel hybrid system with relatively simple structure and control. It may be a better choice, and this kind of program has been tested by many domestic OEMs;

For companies that have already patented planetary transmissions, the PS structure is a good choice if they have the corresponding mechanical and electrical control technology.

For pure electric

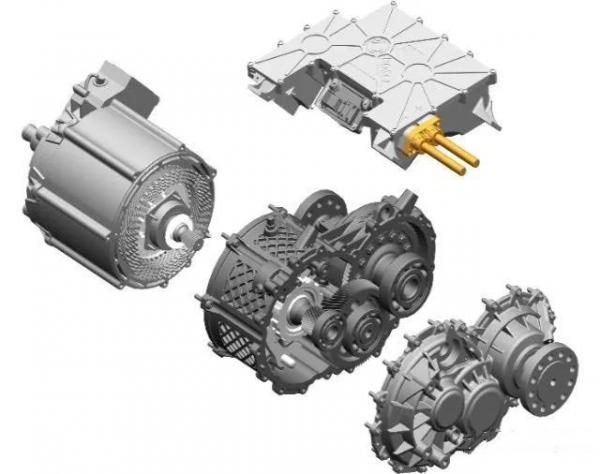

Based on external requirements such as “new four”, simple and compact structure will be an important proposition, so the eAxle system (ie, the three-in-one depth integration of motor, motor controller and reducer) is an important solution around this proposition. Program.

It’s not enough to just laugh at the rivers and lakes by sturdy foundations. The cultivation of some special skills will be the key to determining the outcome:

Skill 1: "Integration." Component integration and functional integration will be an important aspect. High mechanical integration will require components with higher vibration resistance. For example, the 3g/5g vibration resistance level required for the controller may need to be increased to 10g or higher. Better thermal performance design, all-in-one integration not only requires mechanical fusion, how to design the cooling circuit, and ensure that the thermal performance test of each component under all-in-one conditions will be a point to consider. At the same time, the deep integration of multiple controllers will also form another nirvana.

Skill 2: "Performance Optimization." Designing higher current capability and power density controllers to meet the system's need for output power and torque boost, while also requiring a better system output efficiency.

Skill 3: "Diversified functions." This is not only a simple superposition of the functions of the original components, but also more consideration of the introduction of external data, but also needs to consider the function fusion and optimization between the controller and the controller. Then the real-time optimal control strategy of the vehicle with integrated external environmental road information, based on big data-driven component fault pre-diagnosis, maintenance tips and maintenance functions will also become the third largest weapon in the decisive battle martial arts.

All in all, to cope with the challenges of the new trends under the new trend, both internal and external training is essential. For the joint electronic power drive business department, after nearly ten years of development, it has already accumulated and researched in the new energy electric drive system, and with solid local R&D and manufacturing capabilities and global cooperation of the Bosch Group, For the technical characteristics of major OEMs, we can help companies to cope with various challenges in the future. With the continuous advancement and development of the United Auto Electronics, it will eventually stand on the top of the "Wulin".

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite

![[New energy] - electric motor principle](/upload/image/20170519/20170519090819_74516.jpg)