Chinese name electric vehicle electric motor law electromagnetic induction law to achieve the conversion or transmission of energy types of electromagnetic devices

1 Product Category

2 Performance requirements

3 R & D history

4 Market conditions

5 working principle

6 Maintenance

7 Troubleshooting

8 Development Prospects

edit

Electric vehicle motor can be divided into AC motor, DC motor, AC / DC dual-use motor, control motor (including stepper, speed, servo, auto-angle, etc.), switched reluctance motor and signal motor and so on. Suitable for electric drive electric motor can be divided into DC motor

Electric vehicle motor

(A motor that converts DC electric energy into mechanical energy) and an AC electric motor (a motor that converts AC electric energy into mechanical energy). Nowadays, DC motors, AC induction motors, permanent magnet brushless motors, switched reluctance motors and so on have been applied in electric vehicles.

Performance requirements

edit

Car driving is characterized by frequent start, acceleration, deceleration, parking and so on. High torque is required at low speed or climbing, and low torque is required at high speed. The motor speed range should be able to meet the car from zero to the maximum speed requirements, which require the motor has a high specific power and power density. Electric vehicle motor should meet the main requirements can be summarized as the following 10 areas:

Electric vehicle motor

(1) high voltage. In the permissible range, it is possible to reduce the size of the motor and the size of the wire and the like by using a high voltage as much as possible. In particular, the cost of the inverter can be reduced. The operating voltage is increased from 274 V THS to 500 V THS B; the maximum power is increased from 33 kW to 50 kW and the maximum torque is increased from 350 N "m to 400ON" m under constant size conditions. Can be seen, the application of high-voltage system on the car's dynamic performance is extremely beneficial.

(2) high speed. Electric vehicles used in the induction motor speed can reach 8 000 a 12 000 r / min, high-speed motor smaller, lighter, and help reduce the quality of equipment loading.

(3) light weight, small size. Motor through the use of aluminum alloy shell and other ways to reduce the quality of the motor, a variety of control devices and cooling system materials should also be possible to use lightweight materials. Electric vehicle drive motors require a high specific power (motor output power per unit mass) and in a wide range of speed and torque have a higher efficiency, in order to achieve lower vehicle weight, extended driving range; and industrial drive Motors typically compare power, efficiency and cost considerations, and optimize efficiency around the rated operating point.

(4) The motor should have a large starting torque and a wide range of speed control performance to meet the start, acceleration, travel, deceleration, braking and other required power and torque. The motor should have automatic speed control function to reduce the driver's handling strength, improve driving comfort, and can achieve the same with the internal combustion engine accelerator pedal control response.

(5) electric vehicle drive motor needs 4 to 5 times the overload to meet the short-term acceleration and maximum climbing grade requirements, and industrial drive motor requires only 2 times the overload on it.

(6) electric vehicle drive motor should have a high controllability, steady state accuracy, dynamic performance, to meet the coordinated operation of multiple motors, and industrial drive motor only to meet a particular performance.

(7) the motor should have a high efficiency, low loss, and in the vehicle deceleration, braking energy recovery.

(8) electrical system safety and control system security should meet the relevant standards and regulations. Electric vehicles of various power battery and motor operating voltage can reach 300 V or more, it must be equipped with high-voltage protection equipment to ensure safety.

(9) can work reliably under harsh conditions. Motor should have a high reliability, temperature and moisture resistance, and low noise in the run-time, can be more harsh environment for long-term work.

(10) The structure is simple, suitable for mass production, the use of easy maintenance.

edit

In 1949, the country's total installed capacity of 1,848,300 kilowatts, the country is only one of the few motor repair shop; 1958 Shanghai Electrical Machinery Plant to create the world's first dual-water internal cooling generator (Wang Geng academician, academician Wang Yusheng); The electric machine (Gu Guobiao Academician began to study in 1958) Dongfang Electrical Machinery Factory (Rao Fangquan academician) with evaporative cooling modification Lijiaxia 400MW hydro generator 4 generators; in 2003 reached 390 million kilowatts, 211 times in 1949, Harbin and Sichuan, the three power generation equipment manufacturing group as the backbone of the manufacturing enterprise group.But the per capita installed capacity of less than 0.3 kilowatts, China's per capita electricity consumption is only equivalent to the world level of 1/3.

market outlook

edit

China's small and medium-sized motor has a certain scale of production enterprises have more than 300, the production of electrical products have more than 300 series. Nearly 1 500 varieties. In 1997 China's small and medium-sized motor production is about 25288MW, in 1998 about 42505MW, in 1999 about 4200MW. Motor exports of about l 7 O00MW. Can be seen in 1998 compared with 1997, motor production has greatly improved, to the I999 years, the amount of electrical production models are down, corporate debt continues to rise. The benefits continue to decline, the industry overall situation has declined. However, with the deepening of reform and opening up, the national macro policy adjustment and the promotion of market demand, China's electrical products from labor-intensive, resource-intensive to high value-added and high-tech products, export product structure gradually In the market and the physical and chemical.

China's more than 300 small and medium-sized motor enterprises are mostly concentrated in the coastal areas of the western region of the few companies in the country's western development opportunities for the motor industry in the development of an opportunity to provide development. In addition, China's accession to the WTO after the domestic part of the rich production capacity of the motor shift to foreign hit, but also a way out of development. In the international market, the motor is an important part of the mechanical and electrical products, the annual trade volume of about 3.5 billion US dollars, the small motor industry stand-alone export products mainly for the exchange of electric motors, alternators and DC motors.

At present, China's annual exports of about 40 manufacturers, exports of countries and regions of more than 60, the main distribution is the largest in Southeast Asia, followed by Europe and the United States, Japan Feng, Canada and other countries. According to the small motor industry survey of nearly 80 enterprises. The export volume of the products was 3 917.4 MW in 1996, 4 6 3 8 MW in 1997 and 4456 MW in 1998. According to customs statistics: medium and small motor exports in 1996 3 768MW, 1997 4 532 ~ 1W, 1998 6 721MW and 1999 7O00MW. in. Small motor output accounted for when Xin Xin annual output of about 10%, about a foreign exchange respectively. I4 billion dollars, 156 million dollars, 185 million dollars and 220 million dollars. Accounting for about 3% to 5% of world trade, share is very small. From this we can see that the development of small and medium-sized motor or a great development space.

Electric vehicle motor

According to statistics, China's motor power consumption accounts for more than 60% of the country's electricity consumption, including small three-phase asynchronous motor power consumption accounts for about 35%, so the development and promotion of efficient motor in China is to improve energy efficiency, one of the important measures, International development trend.

China is now available with the production of high-performance motor technology conditions, but the market conditions are not mature enough, production and market capacity are small. In 1999, the domestic market share of high-efficiency motors was only 2%, 4.7% in 2000, and only 6.5% in 2001, of which more than 70% were exported.

edit

What is a motor?

A: The motor is the battery electrical energy into mechanical energy, electric vehicle wheels to rotate the components.

2, What is the stator?

A: Brush or brushless motor work does not rotate part. Wheel-type brushless or brushless toothless motor motor shaft called the stator, such a motor can be called within the stator motor.

3, what is the rotor?

A: There is a brush or brushless motor working part of the rotation. Wheel-type brushless or brushless toothless motor casing called the rotor, such a motor can be called the outer rotor motor.

4, What is carbon brush?

A: There is a brush motor inside the top surface of the commutator, the motor rotation, the power delivered to the coil through the commutator, because its main component is carbon, known as carbon brush, it is easy to wear. Should be replaced regularly, and clean up carbon deposition.

5, what is the brush grip?

A: In the brush inside the motor to hold and maintain the position of the carbon brush mechanical guide groove.

6, what is the commutator?

A: Brush the motor inside, with a mutual insulation of the strip-like metal surface, with the motor rotor rotation, strip metal alternating contact brush positive and negative, to achieve the motor coil current direction of the positive and negative alternation, complete brush motor coil .

7, what is the phase sequence?

A: The order of the brushless motor coils.

8, what is the magnet?

A: Generally used to address the high magnetic field strength of magnetic materials, electric vehicle motors are NdFeB rare earth magnet.

9, what is a brush motor?

A: The motor work, the coil and the commutator rotation, magnet and carbon brush does not turn, the coil current direction of the alternating change is * with the motor rotation of the commutator and brush to complete. Brush motor in the electric car industry has high-speed brush motor and low-speed brush motor. Brushless motor and brushless motor there are many differences, can be seen from the name of a brush motor brush, brushless motor without carbon brush.

10, What is a brushless motor?

A: The controller provides DC current of different current direction to achieve the alternating current direction of the coil inside the motor. There is no brush and commutator between the rotor and the stator of the brushless motor.

11, the motor how to achieve commutation?

A: Brushless or brush motor in the rotation, the motor coil inside the power direction need to be alternating, so as to achieve continuous motor rotation. Brush motor commutation * commutator and brush together to complete, brushless motor * controller to complete.

12, what is phase?

A: Brushless motor or brushless controller in the three-phase circuit, a phase can not work. Phase failure and phase loss of the main phase. The performance of motor jitter can not work, or turn the weak and noisy. Controller in the phase-phase operation is very easy to burn.

13, motor common types which have?

A: The common motors are: brush with gear wheel motor, brushless gear wheel hub motor, brushless gearless hub motor, brushless gear hub motor, side hanging motor.

14, from the type of motor is how to distinguish between high and low speed motor?

A: A brush with gear wheel motor, brushless gear wheel hub motor is a high-speed motor;

B brushless gear wheel hub motor, brushless gearless hub motor is low-speed motor.

15, the motor is how the definition of efficiency?

A: The motor efficiency is the ratio of the mechanical energy output from the motor to the power supplied by the power supply. The letter "り" said.

16, brushless motor is how to classify?

A: From the phase angle can be divided into two categories, namely divided into 60 ° and 120 ° phase angle of the brushless motor; according to the speed points can be divided into high-speed brushless motor and low-speed brushless motor; whether the motor has Position sensors to points, is divided into a position sensor brushless motor and brushless motor without position sensor.

17, what is the position sensorless brushless motor?

A: For the sensorless brushless motor must first be the car pedal up, so that the motor has a certain rotation speed, the controller can recognize the brushless motor phase, then the controller can power the motor. Because it can not achieve zero-speed start, so very little. But because there is no sensor, all one less point of failure, and its lower cost.

18, brushless motor Hall of the approximate power consumption is the number?

A: The brushless motor Hall power consumption range is roughly 6mA-20mA range.

19, brushless motor Hall voltage range is how much?

A: The brushless motor Hall voltage range is generally 3-24V.

20, the general motor in how high the temperature to work properly? Motor can withstand up to how high the temperature?

A: If the measured motor cover temperature exceeds 25 degrees above the ambient temperature, indicating that the motor temperature rise has gone beyond the normal range, the general motor temperature should be below 20 degrees. General motor coil is made of enameled wire wound, and enameled wire in the temperature is higher than about 150 degrees when the film will fall off because of high temperature, resulting in short-circuit coil. When the coil temperature is above 150 degrees, the motor case shows a temperature of about 100 degrees, so if the shell temperature is based on the maximum temperature of the motor is about 100 degrees.

21, the motor temperature should be below 20 ℃, that is, the temperature of the motor cover more than the ambient temperature should be less than 20 ℃, but the motor over 20 ℃ fever What is the reason?

A: The direct cause of the motor heating is caused by the large current. Generally may be coil short-circuit or open circuit, the magnetic motor demagnetization caused by low efficiency of the motor, the normal situation is the motor for a long time high-current operation.

22, how to measure the phase angle of brushless motor?

A: Turn on the controller power supply, from the controller to the Hall element power supply, you can detect the brushless motor phase angle. The method is as follows: With a multimeter +20 V DC voltage file, and the red table pen then +5 V line, black table pen were measured three high and low voltage lead (here the use of red and black test pen has a skill), by 60 ° and 120 ° motor can be compared to the phase table.

23, if the 60 ° brushless controller used in 120 ° brushless motor, what will happen, and vice versa?

A: The phenomenon will lead to phase loss, can not be normal; but the Tianjin Song is developing an intelligent brushless controller can automatically identify 60 ° motor or 120 ° motor, which can be compatible with two kinds of motor adaptation, making maintenance replacement Easier.

24, brush high-speed motor and brush low-speed motor What is the difference between the visual?

A: A. high-speed motor has a clutch (like a flywheel-like function), in one direction to easily turn to the other direction to effort; low-speed two-way motor rotation are as easy.

B. High-speed motor car when the noise is larger, low-speed motor rotation noise is small. Experienced people can easily identify with the ear.

25, the motor starting current is how to define?

A: The general requirements of the motor starting current can not exceed its rated current of 2 to 5 times, which is why the controller to do the current limiting protection is an important reason.

26, the market sales of motor speed is getting higher and higher and why?

A: A supplier speed can reduce costs, the same low-speed motor, the high speed of the coil turns less, but also save the silicon steel sheet, the number of magnetic steel is also less, buyers think that high speed is good.

B. rated speed work, its efficiency unchanged, but in the low-speed zone was significantly lower efficiency, that is, start-up weakness.

C. low efficiency, need to start with a large current, riding current is also large, the current limit of the controller requirements of the battery is not good.

27, there is abnormal heating motor how to repair?

A: The maintenance method is generally to replace the motor, or for maintenance.

28, the motor's no-load current is greater than the reference table limit data that the motor has failed, what are the causes? How to repair?

A: The mechanical internal friction motor; coil short-circuit; magnet demagnetization; DC motor commutator coke. Maintenance of the replacement method is generally the motor, or replace the carbon brush, clean up carbon deposition.

29. What are the maximum no-load no-load currents of the various motors?

Motor type Rated voltage 24V when the rated voltage 36V

Side hanging motor 2.2A1.8A

High Speed Brush Motor 1.7A1.0A

Low Speed Brush Motor 1.0A0.6A

High Speed Brushless Motor

Low Speed Brushless Motor

30, people feel when riding slow, strong sense of sluggishness

(1) front brake or brake (up gate) and the rotating parts of the friction → adjust the front and rear brake and rotating parts clearance, it is necessary to make flexible rotation, but also to ensure good braking performance.

(2) The chain is too tight → adjust the front and rear axle position

(3) front and rear shaft and shaft parts and caps too tight or wear parts → loosen fasteners, or replace the wear parts.

(4) before and after the tires inflated enough → tires to the foot.

31, the battery is sufficient but the load on the case of two red lights

(1) the charger output voltage is low → follow the charger repair method troubleshooting.

(2) the battery charging time is short → recharging to extend the charging time.

(3) the battery pack or a single capacity drop → press the battery box repair method troubleshooting.

(4) the electrode is damaged or bad → replace the electrode.

32, there are driving in the stop, when the fast slow, weak and other feelings

(1) seven-core connection → bad for seven core.

(2) Hall power brake brake → bad power switch to the brake lever.

33, the battery is sufficient, full-bright display, but unable to load the wheel hub

(1) gear wear slippage → replacement gear.

(2) wheel motor part of the short-circuit winding → replace the motor.

(3) bicycle assembly problems or parts wear → replace the damping rubber.

34, electric drive has irregular stop

(1) controller and the electrical hub connector loose or poor conductive → re-plug the connector or replace the plug-in.

(2) wheel motor carbon brush and rotor contact → failure by wheel repair methods.

35, power-driven noise

(1) hub gear oil shortage → open the wheel, coated with gear grease.

(2) Gear defective → Replace the gear.

(3) gear housing bearing damage → replace the bearing.

Before disconnecting the motor, first unplug the motor and the controller lead. Make sure to record the one-to-one correspondence between the color of the motor lead and the color of the controller lead.

Before opening the motor cover, clean the work area to prevent debris from being sucked into the magnets in the motor. Do the marking of the relative position of the end cap to the hub. Caution: Be sure to loosen the screws diagonally to avoid deformation of the motor housing.

edit

Electric vehicle motor maintenance and maintenance points:

1, the motor wiring: the motor leads to the four cables marked as follows: A1 - armature winding ends, A2 - armature winding ends, D1 (D3) - series winding first end, D2 (D4) Winding end. D2 and A1 are connected, in D1 and A2 between the voltage, the motor can be rotated. To reverse D1, D2 or A1, any set of A2 can be reversed.

2, the motor commutator side open four inspection windows for observation and maintenance commutator and replace the brush with.

3, the minimum allowable insulation resistance of the motor (250V megger): 45V motor is 0.5MΩ, 45-100V motor 1 MΩ.

4, if necessary, should be brushing the commutator between the small groove and commutator surface carbon powder.

5, the motor does not allow high-speed idling start.

6, regularly open the blinds to check the part and the brush is normal.

Troubleshooting

edit

(1) electric vehicle instrumentation is normal, the motor does not turn the reasons for failure to brake failure to determine

② speed to turn damage to judge

③ motor damage judgments

The controller is damaged

(2) Troubleshooting

① Unplug the brake socket (normally open type brake handle). If the motor is running, compared to brake failure, should replace the brake handle.

② turn the source voltage 5V normal, detection turn signal voltage, turn the turn, the signal voltage should be 0.8 ~ 4.2V from low to high changes. Such as no change in voltage and less than 1V, turn the switch to turn the fault or short circuit. If the voltage is greater than 1V and the change is normal, the detection motor Hall signal (yellow, green, blue line). If the three-phase Hall signal line voltage is 5V and good contact, the motor Hall damage, should replace the motor or motor Hall components.

③ Motor signals are detected separately, and the motor is slowly turned by hand. The voltage of each phase should be changed between 0 ~ 5V. If the voltage is not changed, the motor Hall will be damaged. Replace the electric motor or the motor Hall element. If each phase voltage conversion is normal, and the power supply is normal, the controller is damaged, replace the controller.

④ with a multimeter to detect the controller power supply input voltage, the voltage should be greater than 36V (battery fully charged), such as no voltage, should check the input line. Check the controller turn the power supply voltage (then turn the red, black line), the normal voltage in the 5 ~ 6V, such as no 5V voltage, pull the switch to the socket, voltage recovery 5V, the motor may be short-circuit components, such as Still no 5V voltage, the controller failure, the controller should be replaced.

⑤ first check the speed switch and electric car motor Hall at the beginning of whether the short circuit, usually after the rain is more likely to cause damp joints short circuit, so pay attention to turn the connector waterproof, if the controller is damaged before the replacement of the new controller should first check Switch and motor Hall switch is short-circuit? Otherwise it will cause continuous damage to the replacement controller!

⑥ or the motor does not turn, the focus check motor Hall switch and turn signal, if a power, the controller shell is very hot, usually within the controller power short-circuit, should immediately cut off the power.

Prospects

edit

The development history of electric vehicles is the spiral of history. From 1834, American Davenport (Davenport) in the Brandon Street demonstration of his own small battery car manufacturing began, the progressive development of electric vehicles to flourish. The end of the 19th century, car manufacturing success, because the car's performance is much higher than the electric car, so that electric cars are excluded. The 20th century, 60 years, cars have become the main source of pollution in the city, the oil crisis in the 1970s, which makes the electric car has been re-attention. Governments began to develop regulations to develop electric vehicles. The automobile industry has become a pillar industry of the national economy. The automobile has become an indispensable part of people's life. But at the same time, the automobile has caused serious pollution to the city, and the proven oil resources can only be developed and used for more than 40 years. Therefore, the study of high-performance electric vehicles to replace the car is a historical necessity. At present, the development of the world's electric vehicles from the test run to promote the application of the direction of the transition: Japan since 1996 to domestic sales of goods vehicles, the United States from 1997 to the United States sales of goods vehicles. China's electric car is currently in the development stage. In order to promote international wide-ranging exchanges and cooperation, the State Science and Technology Commission and the Ministry of Machinery Industry in 1996 December 6 to 15 held in Beijing International Electric Vehicle and Alternative Fuel Vehicle Technology Exchange, seminars and exhibitions. On the development of electric vehicles in a variety of issues were discussed. At the same time, domestic and foreign automobile manufacturers and some domestic colleges and universities, scientific research units exhibited their own development of electric vehicles. This meeting reflects some of the latest research results of electric vehicles, electric vehicles can also be seen from the development trend of the motor.

2 restricts the development of electric vehicles key

To electric vehicles and traditional fuel vehicles for comparison, the equivalent of a battery instead of fuel, to replace the motor motor. As the energy density of the battery (energy stored per unit weight, wh / kg) is much lower than the fuel, the performance of traditional motor structure can not be directly applied to electric vehicles, therefore, battery and motor is the core of electric vehicles, The key to the development of electric vehicles.

The Development Trend of Electric Motors

Although a variety of drive motors have long been studied very mature, but they can not be directly applied to electric vehicles, electric vehicles have their own operating characteristics, so the motor used to meet these characteristics in order to obtain high performance.

3.1 The characteristics of electric vehicles

The most significant feature of the electric car is frequent starting and stopping, acceleration and deceleration, rather than running at a constant speed. Electric vehicles are mainly used in the pollution of large cities in urban fixed-line driving and some special occasions, such as airports, stations, docks, warehouses, tunnels and tourist areas and other places. People of electric vehicles a charge travel distance and maximum speed have certain requirements, but the request is not very high. General 1 charge driving 50 ~ 100km, the maximum speed of 100km / h or less to meet the requirements. In the long run, electric vehicles to replace the fuel vehicle, its performance must be compared with fuel vehicles, so it's a charge travel distance and maximum speed should be greatly improved. In addition, the reliability and price is also more concerned about the issue.

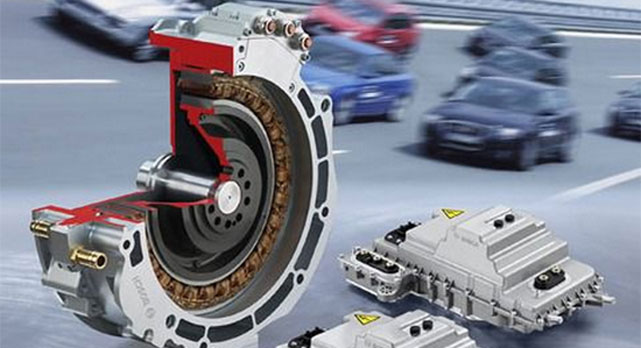

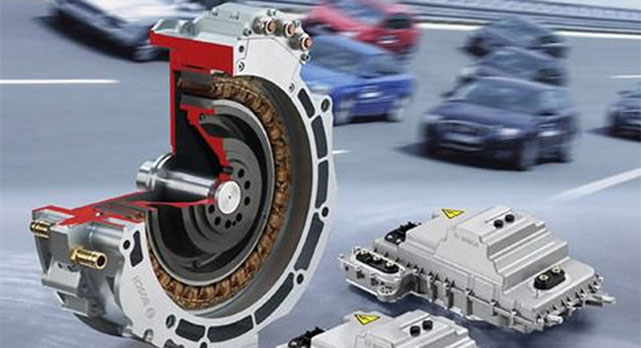

3.2 electric vehicle motor should have the characteristics

Based on the characteristics of electric vehicles, the use of the motor should have certain requirements. In order to increase the maximum speed, the motor should have a high instantaneous power and power density (w / kg). In order to improve the driving distance of a charge, the motor should have a higher efficiency, and the electric car is variable speed work, so the motor should have a high high-speed comprehensive efficiency. Electric car starting and climbing at low speed, but requires a larger torque; normal operation requires less torque, and high speed, so the motor for electric vehicles, the typical mechanical characteristics of the curve shown in the figure. That is constant torque characteristics at low speed, high speed constant power characteristics, and the motor speed range should be wide. In addition, the motor should be rugged, reliable, and the price is low.

3.3 The development trend of electric motor

In the early development of electric vehicles, the use of DC motor. In the trial bus with a series motor, in small passenger cars and small trucks with shunt, compound excitation motor. With the development of permanent magnetic materials, permanent magnet DC motor has also been applied. DC motor has the advantage of a better control characteristics. But it is heavy, low efficiency, expensive, and because the existence of brushes and slip rings, the need for maintenance, brush wear will cause unsafe work. Therefore, with the development of power electronic devices, AC motor gradually mature, DC motor gradually replaced by AC motor. The meeting of the motor exhibitors also use AC motor-based.

Asynchronous motor with its low cost, high reliability, high speed, low torque ripple / noise and without the advantages of position sensors and other advantages were first selected, the vector control of the asynchronous motor more with its excellent performance has become the first choice for electric vehicles. This exhibition of the United States General Motors EVl, Ford Motor Company's Ranger EV and domestic Yuanwang company's electric bus are used asynchronous motor. To. EVl, for example, the performance of the schedule, EVl is the 1990 Chicago Motor Show caused a sensation "impact" (Impact) concept car commercial vehicle. It can be seen, it's driving range and maximum speed have reached a high value. But at the same time, the motor power is very high, the battery voltage is high, its performance and the motor power or battery voltage ratio is not high. This is due to the presence of relatively large copper loss of the asynchronous motor, so that efficiency. Especially at low speed, the efficiency is lower, this is its fatal weakness.

Electric vehicle motor

AC permanent magnet motors, represented by permanent magnet synchronous motors and brushless DC motors, are widely used in the field of electric vehicles because of their low weight and high efficiency. The price of such motors is high, but with the mass production and permanent magnetic material prices fall further, its price will decline. This type of motor also has its weaknesses due to power

Rate of power supply voltage limit, the primary winding turns can not exceed a certain value. Therefore, it is difficult to provide the required output power for the motor by increasing the rotational frequency and without increasing the current. That is, at high speed to provide sufficient output power must increase the current, which consumes a lot of power, reducing efficiency; if not increase the current, the output power down, the electric car can not run properly. This exhibition is the use of permanent magnet synchronous motor representative of the Japanese Toyota RAV4 EV, the use of brushless DC motor is representative of Tsinghua University and other developed electric light buses and the Chinese Academy of Sciences Beijing Sanhuan the company's electric car. Their performance is shown in the attached table. RAV4 EV using a high-performance nickel-metal hydride batteries, the maximum speed and driving range are high, has reached the practical stage. Tsinghua University and the three-ring electric vehicles using lead-acid batteries, indicators are also high.

Switched reluctance motor structure is simple, compact, strong, high efficiency, low speed can provide great torque, and the drive structure is simple, it has been predicted by experts as a dark horse in the field of electric vehicles. Its shortcomings are mainly vibration and noise. This exhibition uses a typical reluctance motor electric car is the Fiat Italian company Fiat 500 electric vehicles, the performance see schedule. It can be seen that, under certain power, it can provide a larger maximum torque, the maximum torque and power ratio.

It can be seen that electric motors use a variety of electric motors have their own advantages, while they have their side, so that they are not fully suitable for electric vehicles. Therefore, it is the task of the electric motor worker to continue to develop the electric motor applicable to the electric car. Harbin Institute of Technology, the study of multi-state motor is such an attempt. This is a hybrid type of stepper motor and asynchronous motor structure in one of the motor, that is, in the traditional hybrid stepping motor rotor slot configuration of a cage winding, the stator core is divided into two sections, two An axial electromagnetic field coil is placed between the stator cores, and the rest of the structure is the same as the hybrid stepping motor. At low speed, the stator winding of the motor is supplied with the hybrid stepping motor, and the motor is operated as a hybrid stepping motor. At high speed, the stator winding of the motor is supplied with the asynchronous motor, and the axial electromagnetic field coil is energized to generate an axial magnetic field for the demagnetization of the magnet, so that the magnetic steel does not produce or have little influence on the motor operation. Asynchronous motor operation. In this way, this kind of multi-state motor has the advantages of high efficiency of high-speed and high-speed of hybrid motor at low speed, high comprehensive performance of high and low speed and wide operating speed range. The EV96-1 electric car is the use of this multi-state motor, the current motor is still being developed.

3.4 The development trend of drive mode

Conventional fuel vehicles include the engine drive system, reducer and differential. This is because the speed range of the internal combustion engine is narrow, and a speed reducer has to be used to expand the speed range. Use differential is easy to turn. Reducer and differential for a series of transmission gear, they consume part of the vehicle running mechanical energy, the wheels get less than the power of the engine 2/3, greatly reducing the efficiency of the car. Because of the different characteristics of the motor and the engine, electric vehicles can use four drive methods: the same as the traditional fuel vehicles; omit the reducer; further omit differential, motor coaxial drive wheel, the axle drive; the motor directly in the wheel , That is, wheel drive. As can be seen. Wheel drive not only completely eliminates the mechanical wear in the drive, improve the transmission efficiency, but also has the smallest size, the lightest weight, while reducing the failure rate. Therefore, the wheel drive is the best way to drive electric vehicles. At home and abroad on the wheel drive had some research, such as the 26th Tokyo Motor Show, the Tokyo Electric Power Company launched the IZA electric vehicles on the use of four direct drive mode, the maximum speed of 176km / h, 1 Sub-charging distance of 548km (40km / h constant speed), using a nickel-cadmium battery, which was the best performance of electric vehicles, which undoubtedly related to the wheel drive. This exhibition uses wheel drive only two, namely the Chinese Academy of Sciences Beijing tricyclic company and the Harbin Institute of technology electric car. Because the wheel drive control method is more complex, so need to do more work on the control.

4 Conclusion

Electric vehicle motor

A. As electric motor, DC motor has been gradually eliminated.

B. Asynchronous motors, AC permanent magnet motors and switched reluctance motors have been used to drive electric vehicles, they have their own advantages, but also have their own weaknesses, not entirely suitable for electric vehicles.

C. Further research is more suitable for driving electric vehicles electric motor is the task of workers. A multi-state motor is a promising motor.

D. Wheel drive is the best way to drive electric vehicles.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite