At present, lithium-ion batteries are widely used in a variety of portable electronic devices, electric vehicles, but with the continuous development of these devices, based on graphite, intercalation of lithium-ion battery can not meet the needs of social development. In order to further expand the application prospects of lithium-ion battery, a variety of systems of the battery has been the researchers attention. Among them, the lithium-sulfur battery has a high theoretical specific capacity of 1672mAh / g, which is almost 10 times the theoretical specific capacity of the traditional cathode materials such as transition metal oxides and phosphate materials. In addition, sulfur has the advantages of low price and environment friendliness. Is expected to become the next generation of ideal cathode material. The concept of lithium-sulfur battery was first proposed in the 1960s, but it was not until the last 20 years that the relevant research results were more relevant. In this issue, the material network for everyone recommended lithium-sulfur battery ESI high cited articles, according to the cited frequency list of 10 articles and their communication author to be introduced to the relevant areas of the researchers to facilitate The

1、A highly ordered nanostructured carbon–sulphur cathode for lithium–sulphur batteries

Highly ordered nanostructured carbon - sulfur cathode in lithium - sulfur batteries

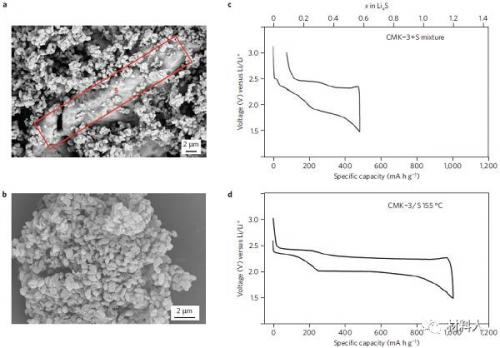

Fig.1 SEM images of carbon-sulfur complexes and their electrochemical characterization

The authors report a highly ordered, interwoven composite carbon - sulfur cathode material, which utilizes the framework of carbon material to limit the dissolution of sulfur during the charging and discharging process, and the preparation of lithium - sulfur batteries with high specific capacity is realized.

2、Graphene-Wrapped Sulfur Particles as a Rechargeable Lithium-Sulfur Battery Cathode Material with High Capacity and Cycling Stability

Lithium-sulfur batteries with graphene-coated sulfur particles with high specific capacity and cyclic stability

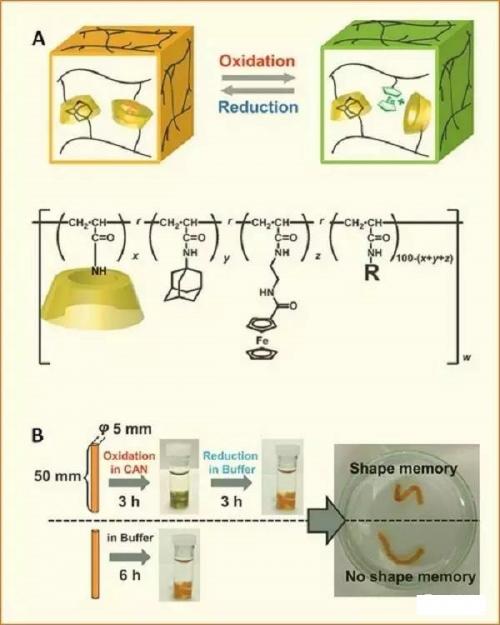

Figure 2 graphene-sulfur composite synthesis steps and the expected composite material diagram

In this paper, a submicron sulfur-coated structure of carbon-modified graphene nanosheet-coated polymer is introduced in this paper. The graphene-sulfur composites are 600mAh after 100 cycles in electrochemical tests. / G, and thus becomes a positive electrode material having a potential for the secondary battery.

3、Porous Hollow Carbon@Sulfur Composites for High-Power Lithium–Sulfur Batteries

Porous hollow carbon - sulfur composites for high power lithium - sulfur batteries

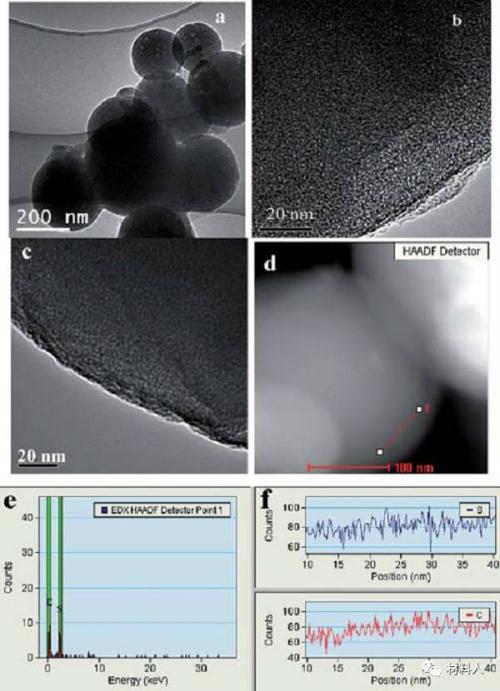

Fig 3 TEM maps of mesoporous carbon hollow spheres, carbon-sulfur nanocomposites and EDX spectra of carbon-sulfur nanocomposites

The authors describe a simple method of synthesizing mesoporous carbon hollow spheres and combine them with sulfur for lithium-sulfur batteries. By electrochemical test, the capacity can reach 850mAh / g after 100 cycles at 0.5C. This method provides a new guiding idea for the nano-structure of lithium-sulfur battery.

4、Graphene Oxide as a Sulfur Immobilizer in High Performance Lithium/Sulfur Cells

High performance lithium-sulfur batteries use graphene as a sulfur fixation agent

Fig.4 SEM and EDX spectra of GO-S nanocomposites after heat treatment at 155 ℃ for 12 h in argon atmosphere

In this paper, the author puts forward the method of chemical immobilization of polysulfide on the reactive functional groups of graphene oxide by the method of dissolving the capacity of the polysulfide dissolved in the lithium-sulfur battery, so that on the graphene nanosheets To obtain a uniform, thin sulfur nano-coating. By electrochemical test, the specific capacity of the battery can reach 950-1400mAh / g, 0.1C magnification can be more than 50 times the cycle.

5、Hollow Carbon Nanofiber-Encapsulated Sulfur Cathodes for High Specific Capacity Rechargeable Lithium Batteries

Hollow Carbon - coated Sulfur Cathode Materials in High Specific Capacity Lithium - sulfur Batteries

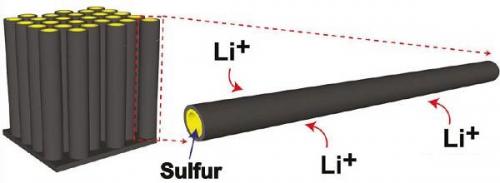

Figure 5 hollow carbon nanofiber / sulfur composite structure design diagram

In order to solve the problem of polysulfide dissolution during the process of charge and discharge of lithium-sulfur battery, the authors propose a structure that encapsulates sulfur with hollow carbon nanofibers, which can effectively limit the dissolution of polysulfide. After electrochemical testing of the battery has excellent cycle performance for the design of lithium-sulfur battery put forward new ideas.

6、Enhancement of long stability of sulfur cathode by encapsulating sulfur into micropores of carbon spheres

The long cycle performance of the battery is improved by encapsulating the sulfur cathode material through the microcellular carbon ball

Figure 6 TEM picture of carbon ball and carbon-sulfur complex, HAADF-STEM picture, EDX spectrum

In this paper, a carbon-sulfur composite anode material for high energy density lithium-sulfur battery was obtained by a simple method of heat treatment of microporous carbon and sulfur. The loading of sulfur in the composite material reached 42wt% Electrochemical tests show that the battery has a long cycle stability.

7、Hierarchically Structured Sulfur/Carbon Nanocomposite Material for High-Energy Lithium Battery

Sulfur - carbon nanocomposite graded structural materials in high energy density lithium - sulfur batteries

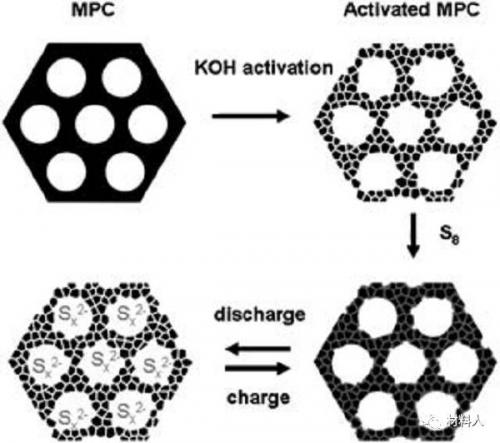

Figure 7 Schematic representation of a sulfur-carbon composite cathode material supported by bimodal porous carbon

The authors first reported a graded sulfur-carbon composite material for high energy density lithium-sulfur batteries. A mesoporous carbon material with pore size of 7.3 nm was synthesized by soft template method. After activation by potassium hydroxide, A bimodal microporous carbon material having a pore size of less than 2 nm is supported on the porous carbon material by dissolving the sulfur. High specific surface area, porosity significantly improved sulfur utilization.

8、Sulfur-Impregnated Disordered Carbon Nanotubes Cathode for Lithium-Sulfur Batteries

Lithium - sulfur battery in sulfur - impregnated disordered carbon nanotubes cathode

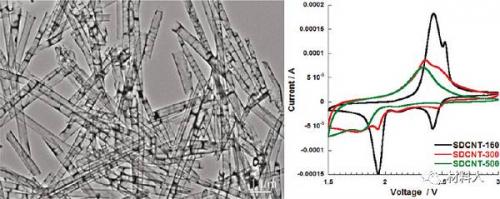

Figure 8 TEM diagram of disordered carbon nanotubes and CV curve of sulfur-impregnated carbon nanotube electrode for the second cycle

In this study, the researchers synthesized sulfur-impregnated carbon nanotube cathode materials, the resulting battery has excellent cycle performance and high Coulomb efficiency. In addition, electrochemical characterization indicates that the heat treatment has a new stabilizing mechanism for the fixation of sulfur in carbon.

9、Smaller Sulfur Molecules Promise Better Lithium?Sulfur Batteries

Lithium sulfur batteries in the small sulfur molecules have better performance

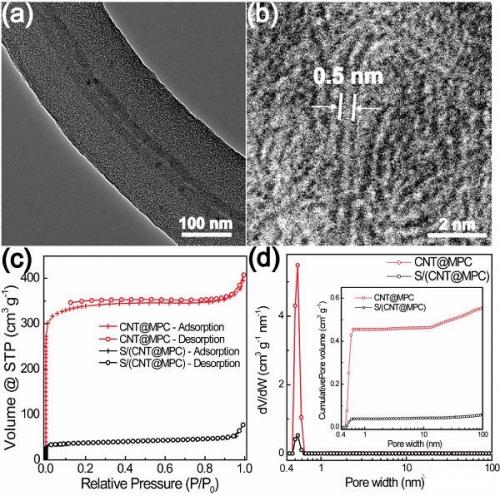

Figure 9 Structural characterization of CNT @ MPC

In this paper, the author discusses the problem of sulfur loss in lithium-sulfur battery, and it is proposed to reduce the loss of sulfur by controlling the size of the sulfur molecule to the smaller allotrope. The synthesis of metastable small sulfur in the network of conductive microporous carbon Molecule S2-4, the small molecule can completely avoid the transition state of macromolecules S8 and S42-.

10、Sulphur–TiO2 yolk–shell nanoarchitecture with internal void space for long-cycle lithium–sulphur batteries

Hollow sulfur-TiO2 core-shell nanostructures are used for long-cycle lithium-sulfur batteries

Figure 10 Schematic diagram of intercalation of lithium in various sulfur-based nanostructures

In order to solve the problem of the volume expansion of sulfur and the dissolution of polysulfides in lithium-sulfur batteries, a core-shell structure of TiO2-coated sulfur was synthesized and a swell volume space was reserved for sulfur in the TiO2 shell. This work provides a constructive idea for the application of volume expansion materials in electrodes.

The above article part of the communication author and its brief introduction:

Linda F. Nazar, professor of chemistry, electronics and computer engineering at the University of Waterloo, Canada, is a prominent scientist in the world of battery research, specializing in energy storage materials and solid electrochemical materials. In 2009, he received the International Electrochemical Society's Battery Research Award, 2010 won the California Institute of Moore Outstanding Scholars Award, in 2011 by the International Lithium Battery Society Award, in 2011 by the International Pure Chemical Society of Chemical Engineering Outstanding Female Scientist Award, 2011 Linda Nazar Dr. was named the Royal Society of Canada members , In 2014 selected Thomson Reuters high lead.

Cui Yi, received a bachelor's degree from the University of Science and Technology of China in 1998, a Ph.D. from Harvard University in 2002, and a postdoctoral fellow at the University of California at Berkeley in 2003 and 2005. He is currently a professor at Stanford University. The main research on nano-materials design, synthesis and performance research and application in energy storage, solar cells, catalysis, water and air purification; two layered materials; topological insulators; nano-biology.

Zhang Yuegang, researcher. From 1981 to 1989, he received a master's degree from Tsinghua University and a doctorate in materials science from the University of Tokyo in 1996. He was a researcher at the National Institute of Electrical Engineering, Stanford University, and Intel Corporation, and is currently a researcher at the National Lawrence Berkeley National Laboratory. From the Chinese Academy of Sciences, Suzhou Institute of nano-technology and nano-bionic declared group of thousands of people plan, and in February 2012 was selected in the group of thousands of people plan.

Gao Xueping, male, researcher at the School of Materials Science and Engineering, Nankai University. Long engaged in new energy materials and chemical power of basic research work. Some of the results have been published in Angew. Chem. Int. Ed., Energy Environ. Sci., Adv. Mater. And Adv. Energy Mater. The paper is cited by SCI more than 9,000 times, h index of 52. Among them, there are 13 articles selected ESI nearly ten years high cited papers. Was selected for 2014 and 2015 Elsevier China Highly cited scholar, selected by Shanghai Software and Elsevier in 2016, "Global Energy Science and Engineering Highly cited scholar." By the 2003 and 2015 Tianjin Natural Science Award (first completed), by the 2005 National Science and Technology Progress Award (sixth completion).

Professor Wang Chunsheng, Professor of Chemistry and Biomolecular Engineering, University of Maryland. In 1995, he received his doctorate degree in materials science and engineering from Zhejiang University. Prior to joining the University of Maryland in 2007, he was an assistant professor of chemistry engineering at the University of Tennessee from 2003 to 2007 and a researcher at the Center for Electrochemical Systems and Hydrogen Research at the University of Texas, 1998-2003. His research focused on secondary batteries and fuel cells.

Wan Lijun, physical chemist. Born in July 1957, native of Dalian, Liaoning. Former Director of the Institute of Chemistry, Chinese Academy of Sciences, he is currently the Director of the National Laboratory of Molecular Sciences in Beijing and the Director of the Key Laboratory of Molecular Nanostructures and Nanotechnology of the Chinese Academy of Sciences. The current president of China University of Science and Technology (vice ministerial level).

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite