At present, we know the various types of electric vehicles in the mileage of how many little let the consumer is not satisfied, so in addition to energy recovery and some other auxiliary technology, the battery "bigger" is the car's important design ideas, so right Body layout, interior space, etc. also put forward a higher design requirements. So, soft, high bending radius of the wiring harness on the compact installation space is particularly important.

Thin-walled wire is a good choice for improving the softness of the wiring harness and reducing the space occupied by the wiring harness. However, compared with the thick insulation wall wire, its wear resistance, temperature and pressure resistance will achieve a higher performance Claim.

Everything has to go through an oxidation process, the insulation material on the wire is no exception. Over time, the insulation will become brittle and will no longer provide enough insulation and will eventually be shorted. While the temperature is one of the main reasons to accelerate this aging process.

Unlike conventional wire and cable, in addition to the ambient temperature, hybrid / pure electric vehicle high-voltage wire harness almost all of the time in high-power work, the heat generated by the current heat from inside to inside the cable. This internal heat, a greater degree of accelerated insulation of the aging, cracking. Therefore, the electric vehicle wiring harness high temperature, low temperature, anti-aging performance is also an important consideration.

Resistance to liquids (gasoline, diesel, coolant, battery acid, etc.) performance is also electric vehicles, especially hybrid electric vehicles in the wiring harness design should be taken into account. Insulation is easy to age after contact with the oil short-circuit is also more and more cases confirmed by the accident.

The The The The The The

All of the above performance requirements are common to a technical product - the use of radiation cross-linked wire (XLE). After irradiation processing, the insulation properties of wire and cable, the physical properties, chemical properties can be maximized. For some physical characteristics, please refer to the following comparison chart:

Aging test

Resistance to liquid testing (gasoline) ISO6722

Resistance to liquid testing (diesel) ISO6722

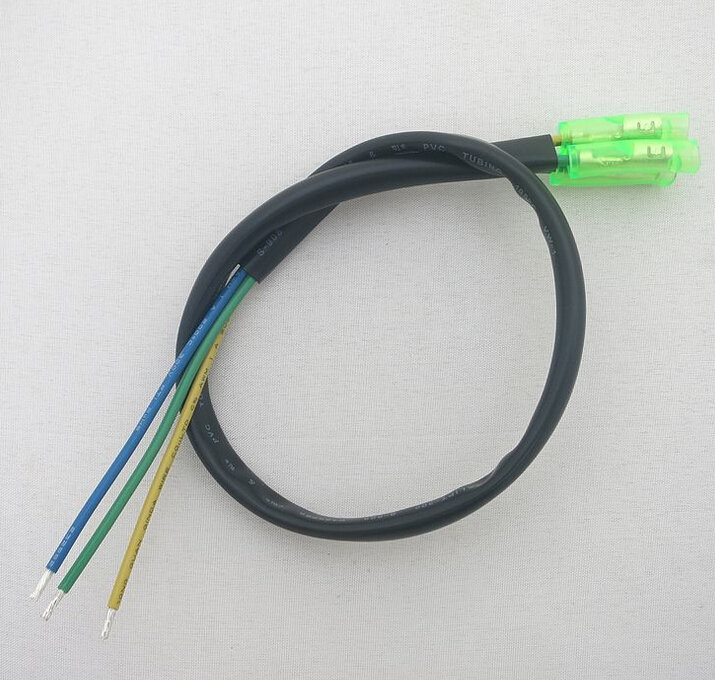

Shenzhen City, the United States and the United States and the new energy connection system Co., Ltd., Russia imported radiation processing equipment, customers can produce various types of high-quality processing, high softness, wear resistance, temperature, pressure, liquid-resistant new energy automotive wiring harness Cable products.

Key words: electric vehicle harness high voltage harness harness production

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite