Harness design process in the wiring harness two-dimensional product drawings come out, to arrange the production process harness production process data, including the preparation of material consumption quota schedule, working hours and so on.

Harness software - midline CAD can perfectly meet this need

The opening process will cut the required wires to the desired length of the first station of the wire harness. The accuracy of the opening process is directly related to the entire production schedule, in the event of errors, especially the open line size is short, will lead to all the station rework, time and effort to affect production efficiency.

Major equipment: wire cutting machine, cutting line machine, peeling machine, stranding machine

Crimping process according to the type of drawings required to determine the crimp parameters, the terminal crimp to the wire, for the special needs of the need, such as: some wires need to wear through the jacket before crimping, it needs to first Installed wire and then returned from the pre-installed station and then crimp; there are puncture crimping with a dedicated crimping tool, this crimp way has good electrical contact performance.

Main equipment: semi-automatic crimping machine, automatic crimping machine (including open process), crimping die, tensile testing machine, the terminal section of the test

Pre-installed process to install connectors such as small shares sub-line. In order to improve the efficiency of the assembly, the complex wiring harness should be set pre-installed station, pre-installed process is reasonable or not directly affect the efficiency of the assembly also reflects a technical level of technical staff.

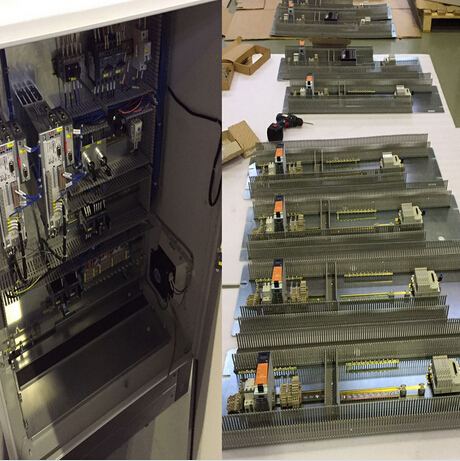

Major equipment: preloaded table, automatic harness connector

Assembly process According to the product development department design of the assembly board, a variety of small sub-line in the large tooling board assembly, tape bandage, installation of various protective parts (bellows, protective bracket, etc.).

Major equipment: assembly line, tooling board

Test process in the dedicated detection board to detect whether the circuit is smooth, the appearance of detection, grommet waterproof testing

Main equipment: conduction test station

Wiring harness production process

Open - Crimp - Preloading - Assembly - Inspection - Electrical Testing - Packaging - Shipping

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite