Vehicle design

First, the power distribution design Automotive power supply system design is reasonable, directly related to the normal work of automotive electrical parts and the safety of the whole car, so the world's automotive wiring harness design starting point are basically security-based.

The vehicle electrical system consists essentially of three parts:

Battery direct power supply system (commonly known as regular or 30 power). This part of the power supply load is generally the car's safety parts or important parts, the main purpose is to provide energy for these pieces as little as possible to control, to ensure that these pieces can not start even if the car can work for a short time to facilitate To the site maintenance and so on.

Such as: engine ECU and engine sensor power supply, fuel pump power supply, ABS controller power supply, diagnostic interface power supply.

Ignition switch control of the power supply system (commonly known as IG file, 15 power or ON device). This part of the electrical device is basically in the case of engine operation and operation only, from the generator power supply, to avoid the power of the battery when the possibility of charging power. Such as: instrument power, brake light power, airbag power and so on.

The power supply (commonly referred to as the ACC power supply) for unloading the load when the engine is started. This part of the electrical parts of the general load is relatively large, and the car does not have to start working. Generally have cigarette lighter power, air conditioning power, Shoufang Ji power, wiper power and so on. 2 line protection design Line protection is to protect the wire, taking into account the protection of electrical equipment. Protection devices are mainly fuses, circuit breakers and fusible lines.

1. The principle of selection of fuses

Engine ECU, ABS and other vehicle performance and safety impact, in addition, susceptible to other electrical equipment interference electrical devices must be a single fuse.

Engine sensors, all kinds of alarm lights and external lights, speakers and other electrical components on the vehicle performance and safety impact is greater, but the type of electrical load on the interference between each other is not sensitive. Therefore, such electrical loads can be combined with each other according to the situation, the common use of a fuse. The electric load of the ordinary electric parts to be set for increasing the comfort can be combined with each other according to the situation, and a fuse is used together.

Fuses are split fast and slow melt. The main components of the fast-melting fuse are fine tin wire, in which the chip fuse structure is simple, reliable and vibration-resistant, easy to detect, it is widely used; slow melting fuse is actually tin alloy, this structure The fuse is generally connected in series to an inductive load circuit, such as a motor circuit.

Resistive load and inductive load are used as far as possible to avoid using the same fuse. Generally according to the maximum continuous working current of electrical components to calculate and determine the fuse capacity, according to empirical formula: fuse rated capacity = circuit maximum operating current ÷ 80% (or 70%).

2. breaker

The biggest feature of the circuit breaker is recoverability, but its cost is higher and the use is less. Circuit breakers are generally thermal mechanical devices, which use two different thermal deformation of the metal, the contact opening or closing or self-connected. A new type of circuit breaker, using a PTC solid material as an overcurrent protection element, is a positive temperature coefficient of resistance that is disconnected or turned on according to the current or temperature level. The biggest advantage of this protection element is to automatically turn on after troubleshooting, without manual adjustment and replacement.

3. Fusible line

Fusible line is characterized by the line through the great overload current, the fusible line in a certain period of time (generally ≤ 5s) fuse, thus cut off the power to prevent the occurrence of malignant accidents. Fusible line is also composed of conductor and insulation layer, the insulating layer is generally chlorosulfonated polyethylene material, because the insulation layer is thick, so look. Up thicker than the same specifications of the wire.

Fuselage line generally connected to the battery directly leads to the circuit. Fuselage commonly used nominal cross-section of 0.3mm2, 0.5mm2, 0.75mm2,1.0mm2,1.5mm2, and even 8mm2 and other larger cross-section of the fusible line. The length of the wire segments of the fusible line is divided into (50 ± 5) mm, (100 ± 10) mm and (150 ± 15) mm.

The fusible line should have a clear mark, and when it is blown, its markings should still be present for easy replacement. The fusible characteristics of fusible lines are shown in Table 1.

3, the choice of relay design The relay is divided into two kinds of current and voltage.

Generally according to the electrical power and the carrying capacity of the switch to decide whether to use the relay. Commonly used relay equipment generally have wipers, speakers, defrost, headlamps, fog lights, fans, blowers, turn lights (flashers) and so on. Relay 6V, 12V, 24V3 kinds of commonly used relay rated voltage of 12V.

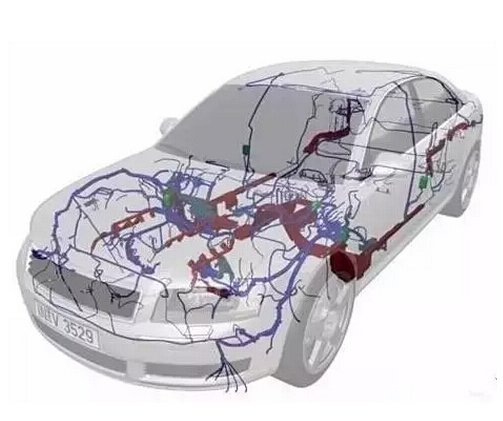

Select the relay to refer to the technical requirements: ① good reliability; ② stable performance; ③ light weight, small size, long life, the impact of small components around; ④ simple structure, good technology, low cost. The three-dimensional layout of the wiring harness to the design This process is mainly simulated simulation of different areas of the wiring harness to the diameter, consider the wiring harness sealing and protection, simulation of the wiring harness fixed and fixed way, as shown in Figure 1. The main software for 3D cabling is PRO-E, UG and CATIA. The design of the connector is the core part of the harness. The performance of the connector directly determines the performance of the harness as a whole, and plays a decisive role in the stability and safety of the whole vehicle.

1, the selection of the principle of plug design plug connector to ensure good contact with the electrical device, so that the contact resistance is reduced to the lowest, improve reliability, preferred dual spring-type compression structure of the connector.

According to the cross-sectional area of the wire and through the size of the current reasonable choice of the connector.

Engine compartment docking jacket, due to cabin temperature, humidity and there are many corrosive gases and liquids, so be sure to choose waterproof jacket.

In the same harness if the same kind of jacket, the color must be different. Based on the overall coordination of the appearance of the car, in the engine compartment should be preferred black or dark jacket.

In order to reduce the type and number of harness for the wiring harness, the mixing type is preferred, and the assembly is easy to fix.

For the requirements of high performance airbags, ABS, ECU and other terminal fittings, should be preferred to use gold to ensure safety and reliability.

2, the connector material (material) performance analysis terminal material (copper pieces)

The copper used in the connector is mainly brass and bronze (brass hardness is slightly lower than the hardness of bronze), which accounted for a larger proportion of brass. In addition, according to different needs to choose a different coating.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite