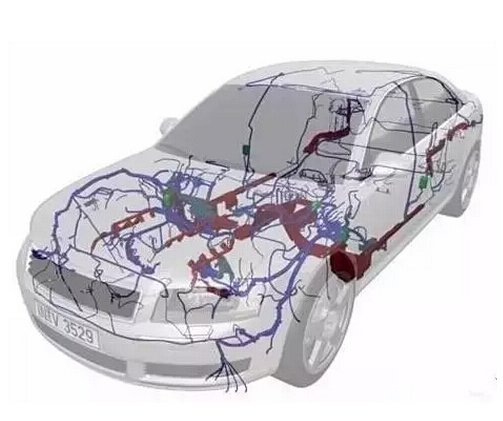

Harness design is a very rigorous work, the accuracy of its design, directly related to the performance and quality of equipment. So the harness design of each link, need to be targeted. For example: design drawings, design samples, size, etc. need to be modified several times to confirm, so as to ensure the quality of wiring harness.

The following is the wiring harness processing process need to understand some of the relevant wiring harness design accuracy and test of the standard, so you can ensure the reliability of the wiring harness product quality, so that the harness finished zero defect to allow customers to use.

1. Crimp the surface insulation should be good, the conductor should not be broken off.

2. Crimp should be firmly, in the provisions of tension should not be damaged and disengaged.

3. Harness wrapping material from the plastic shell tail extension within 25mm, except for a single wire.

4. Voltage drop test requirements: the terminal voltage drop of the detailed requirements of the reference standard QC / T29106-1992.

5. Crimp connection can be used U-type terminal crimping and ultrasonic fusion, etc., need to use a special machine for crimping.

6. Industrial harness label should indicate the location of the plug and print correctly and clear, the label should be attached to the end of the harness at about 50mm, paste firmly.

7. Wire harness connection point should be used wear-resistant woven tape for a fixed bandage, in a waterproof area, connect the nail outside the need to heat shrink tube jacket protection, heat pipe temperature requirements -40 ℃ - +100 ℃.

8. Minimum drawing force test requirements: the connection of the terminal and the wire should be firm, to 200mm / per minute rise speed of the wire after the crimping of the tensile test, the minimum drawing force should be consistent with the provisions.

Design of the wiring harness products, but also through proofing, test testing, technical feasibility of the various aspects of research, can be mass production, so that the design of the wiring harness products to meet customer needs, but also in the production process can also reduce the raw materials The waste, reduce the production of this.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite