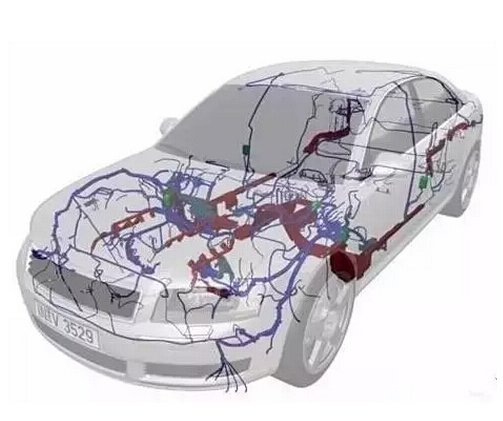

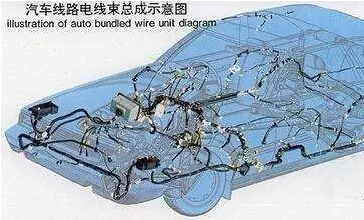

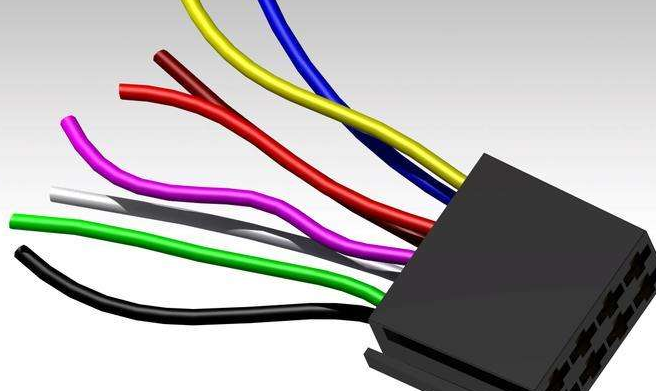

China's auto industry development is basically based on the introduction of the basis of the introduction of the model determines the production of wire harness can only be imitation or equivalent development, so the development of automotive wiring harness technology has lagged behind the development of the vehicle. At present, the popularity of Chinese cars, security, the application is the main type, so the car harness technology will remain at the current level, but with the car family, the car configuration requirements will become more and more diverse, Non-standardized, harness plant production tens of thousands of sets, or even hundreds of thousands of sets of exactly the same harness situation will be broken. The use of non-metallic conductive materials, the integration of the production module will be the first time in recent years to study the topic.

As a result of the automatic detection of high-performance crimping machine come out, piercing the new process, the improvement of new equipment, as well as the vehicle engineering changes frequently, shorten the delivery cycle, traditional, workshop, manual wiring harness production will gradually Was eliminated, so to improve the ability of independent development, parameter design, system design, maintenance and vehicle design synchronization is the main development direction of China's automotive wiring harness industry.

Due to the diversification of the harness function, the vehicle factory will require the parts factory to provide immediate spare parts, will also completely break the traditional mode of production and supply. At present, the more powerful harness factory has been assembled to the location of the vehicle factory to meet the rapid response requirements, in the United States and Europe, the wiring harness factory supply time has been reduced to ninety minutes, which requires the harness plant not only have a quick strain The technical management system and reliable quality assurance system, there must be a smooth material system, as well as personnel training system. China's automobile production base pattern has been basically formed in the vehicle factory driven, has become a base for the production of wire harness scale, northeast, east China harness production accounts for about 63% of the national market, and its ability to sustainable development is better than Other areas.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite