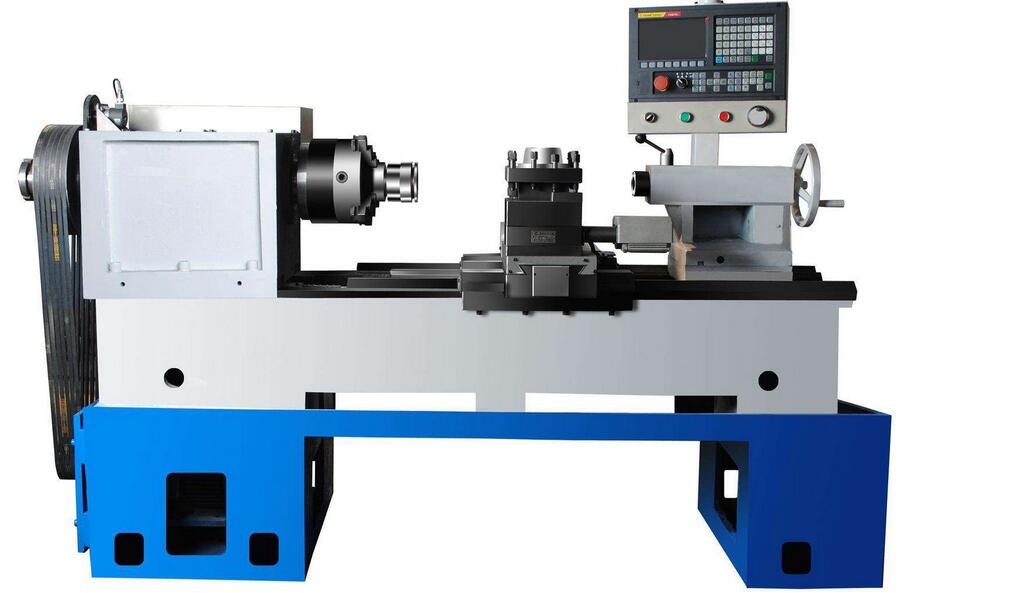

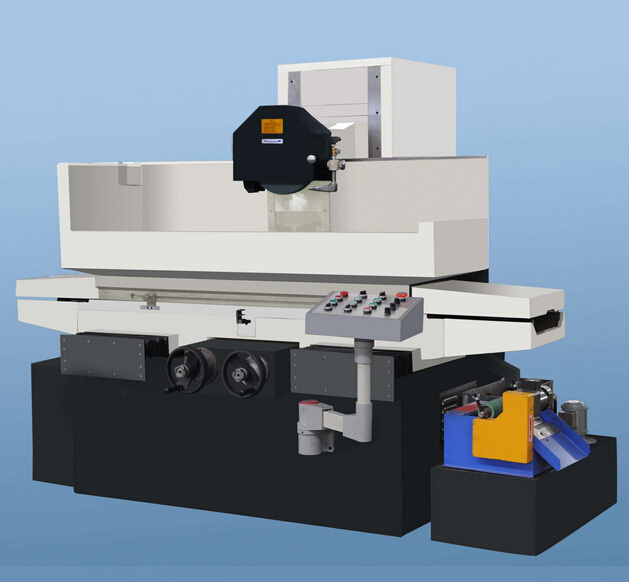

CNC machine tool has now become a new industry, which is booming, occupying an increasingly important position in industrial development, but also by the manufacturer's welcome. CNC machine compared with the traditional machine has a high degree of flexibility to avoid the frequent replacement of the mold process, but also saves manpower, material and financial resources; and CNC machining of high density, generally up to 0.05-0.1MM; most importantly, CNC machine tools to improve the working conditions, so that the operator greatly reduce the labor intensity, risk performance has also been reduced.

First, the principle of mechanical failure diagnosis of CNC machine tools

(A) Now the external post-internal

After the failure, the use of "look and hear" method from the inside to the outside of the body check, such as a variety of switch parts, connecting parts, sensor sensitivity, temperature and humidity, oil mist damage to components and circuit boards.

(B) the first electrical machinery

Mechanical failure is easy to detect, so start with a simple mechanical failure, and numerical control system fault diagnosis difficulty factor is relatively large, not to mention, some electrical faults are caused by mechanical failure. So after the first electrical machinery can reduce the labor waste.

(C) first quiet after the move

Due to the high precision and complexity of CNC machine tools, repairs without related troubleshooting may result in significant losses. Therefore, before troubleshooting, do not blindly hands-on, should understand the process of failure, status, and access to relevant information, analyze the possible causes of failure, and then troubleshooting.

Third, CNC machine tool mechanical fault diagnosis method of application

MNC863T CNC system fault diagnosis: (1) Symptom: The system power is not started. Fault reasons: A. AC220V is not energized to the NC DC power supply; B. The power failure control cabinet open door; C. Machine power on button is damaged; D. System power supply without DC output; E. System board 5V short to the resistance Or leakage analysis; Diagnostic test methods: A. Whether the power into the line 220V input; with the plate, the transformer 220V input and output is normal. B. electric cabinet door open power-off wiring is correct or poor contact; C. test power on button; D. DC power output detection, socket contact is good; E. Meter with a multimeter measuring 5V resistance to ground resistance should be 30Ω or more, If there is a short circuit, unplug the × 10 board, × 20 board, × 30 board. To determine which board has a problem.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite