Fully automatic generator sets must be filled with sufficient fuel when in use. If there is a lack of diesel oil during the operation, the generator set will not cause minor damage. Therefore, before every start-up, check the unit's oil reserve. the amount.

1. Check whether the fuel in the mailbox is sufficient. Observe whether the oil level reaches the marking on the scale. If it is insufficient, add it to the specified amount, but do not exceed the upper limit of the marking line.

2. Check the oil level of the fuel injection pump governor. If the mark of the mark is not reached, add oil (there is no ruler on some fuel pump governors. This step can be omitted).

3. Check whether there is enough grease in the pump's oil injection point. You can remove the oil filling nozzle on the diesel circulating pump and observe whether the grease inside is sufficient. If insufficient, apply the oil gun to inject sufficient grease into it.

Automatic generator set starter operation also needs to pay attention to the following points:

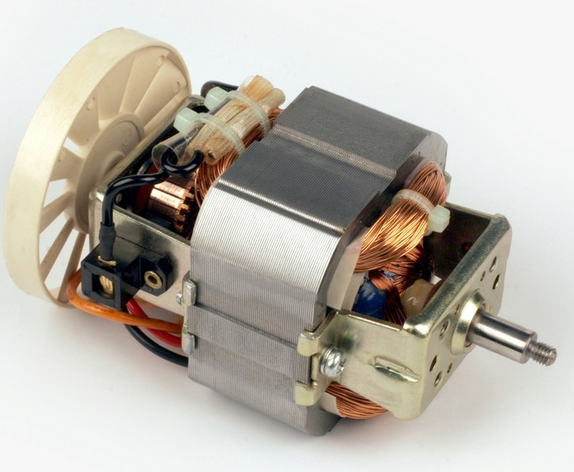

1. The continuous working time of each start of the diesel engine shall not exceed 10S. The interval between two starts shall be more than 2 minutes to prevent the armature coil from overheating and burn out. If you cannot start successfully three times, you should find out the reason and start it.

2. After the unit starts, quickly release the start button to return the drive gear to its original position.

3. The unit must not press the diesel start button again during normal operation.

4. When you hear the drive gear adjusting rotation and cannot mesh with the ring gear, quickly release the start button. After the starter stops working, start the second time to prevent the drive gear and the flywheel ring gear from colliding and damage.

5. When using a diesel generator set in a cold area, switch to antifreeze oil. When starting up, use a screwdriver to pull the flywheel ring gear at the flywheel inspection hole for a few weeks before starting.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite