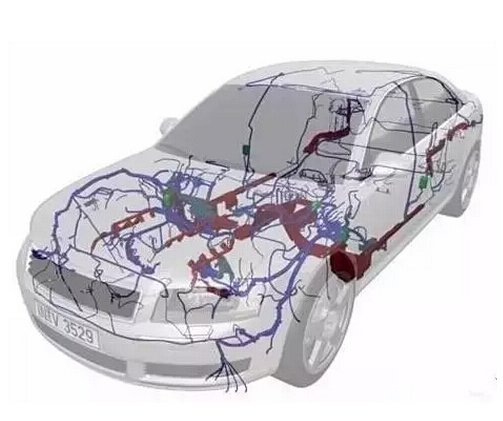

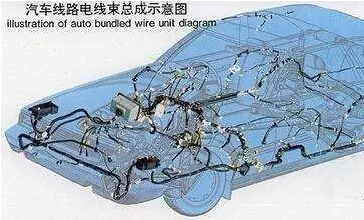

The single-chip hardware detection circuit of the harness detection system can scan the state of up to 256 harnesses. The expansion of the number of detected harnesses can be completed through the CAN bus. Theoretically, one computer can handle tens of thousands of different locations and studios. Harness detection. The main detection principle of the wire harness detection system is that the VB or touch screen will transmit the detection command to the main processor through the serial port after the system is powered. The host processor will send the detection command to the module that needs to perform harness detection through the CAN bus. After the detection command, the current detection module will scan the wire harness through the hardware detection circuit, and then send the detected wire harness status to the main detection processor through the CAN bus. The main detection processor will pass the data information through the serial port to detect the wire harness. The status is transmitted to the host computer. The host computer analyzes the actual harness connection status by analyzing the data information transmitted, so as to determine whether the detected harness is normal, whether there is a short circuit, open circuit, wrong connection, etc., when all need to be detected. After the harness inspection is completed, the system will display the test information and give a qualified test result.

Among them, after the detection module receives the detection command, the MCU will first light up the detection indicator, and then scan to detect whether the two air pump buttons are pressed at the same time. If they are detected at the same time, it indicates that the user has selected the welding. In the detection mode, the microcontroller will control two groups of six motors to rotate at the same time. Finally, the microcontroller will scan and collect the state of the harness of the connector on the experimental stage.

1, the basic detection system

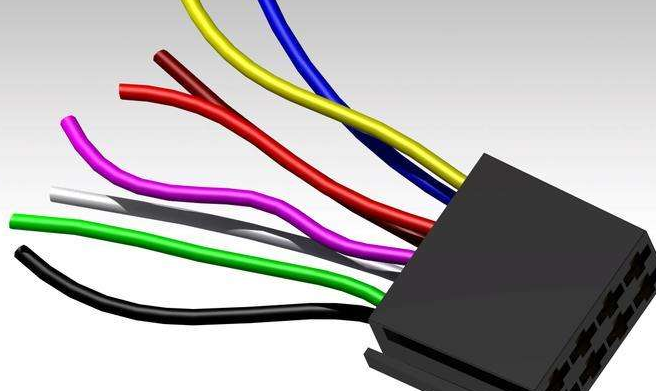

A basic set of harness detection systems includes a basic test board that can detect the connection status of up to 256 conductors. The main components on this test board are an Atmega128 microcontroller and 34 CD4067 chips. There is also a Max232 chip. Its basic detection principle is that the MCU controls the closing of 256 groups of electronic switches consisting of 34 CD4067 chips to detect whether there is a low-level signal through the wires into the MCU, so as to achieve MCU's acquisition of the wire harness conduction state signal.

2. Harness Extension of Harness Detection System

When the number of wire harnesses to be inspected is too large, that is, when a single test board capable of detecting 256 wires has failed to meet the test requirements, the number of test harnesses needs to be expanded, and if the instrument alone is used to achieve high cost, At this time, the CAN bus system works.

The CAN bus communication interface integrates the physical layer and data link layer functions of the CAN protocol and can complete the batch processing of communication data, including bit stuffing, data block coding, cyclic redundancy check, priority discrimination, etc.l. On each board, there are CAN bus control circuits and CAN bus interface circuits. The CAN bus is controlled by the SJA1000. More than 110 physical nodes can be cascaded through the PCA82C250. That is, up to more than 110 test boards can be connected. The number of wire harnesses that can be detected can reach over 20,000, and the CAN bus can be used. The twisted pair connection, and the transmission distance is long, the signal is stable, so each board can be flexibly distributed in various workshops, not all integrated in a device, can be satisfied by a master control device, so it has Very big prospects and advantages.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite