In 2017, the production and sales of new energy vehicles in China reached 774,000 vehicles and 777,000 vehicles respectively. The rapid development of the new energy auto industry will undoubtedly require the support of the country’s new energy policy. However, the financial subsidies for new energy vehicles are gradually tightening. For the new energy automotive industry, every move of subsidies will have a huge impact on the layout and planning of car companies. So how can a car company survive for long?

Subsidy accelerates downward slopes Market enters enterprise-led stage

The rapid development of China's new energy auto industry can not be separated from the policy's strong support, but relying on policies is not an ideal solution for sustainable development. With the industry gradually on the right track, the subsidy policy is gradually declining. According to the new regulations on subsidy policies, all subsidy policies will be withdrawn after 2020, and the Ministry of Industry and Information Technology has also established a new energy auto points trading system as an alternative measure.

Self-hematopoiesis is the long-term strategy

The electric vehicle resource network believes that if an industry wants sustainable and healthy development, relying solely on policy support for passive blood transfusion will not work. It is also necessary for enterprises to learn to self-bloom. So how do you do it? Only by constantly upgrading technology, reducing costs, and manufacturing quality products, and providing a good service experience for customers, can enterprises get rid of the effects of subsidy withdrawal and achieve self-enhanced blood.

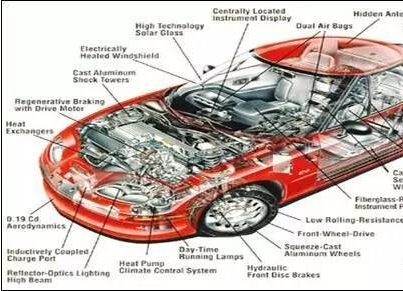

In terms of cost control, power batteries, as the "heart" of new energy vehicles, account for a large part of the cost. Cui Dongshu once said that “the cost of batteries and raw materials is high, mainly because the upstream costs are too high. These upstream companies are also speculating on subsidies for retreat. The state should take measures to curb such behavior and conduct effective supervision. "To reduce the manufacturing cost of new energy vehicles, the primary goal is to power the battery. Only if its cost is reduced, can the vehicle cost be controlled. At present, an effective path for reducing the cost of power battery companies is to realize the scale and standardization of production.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite