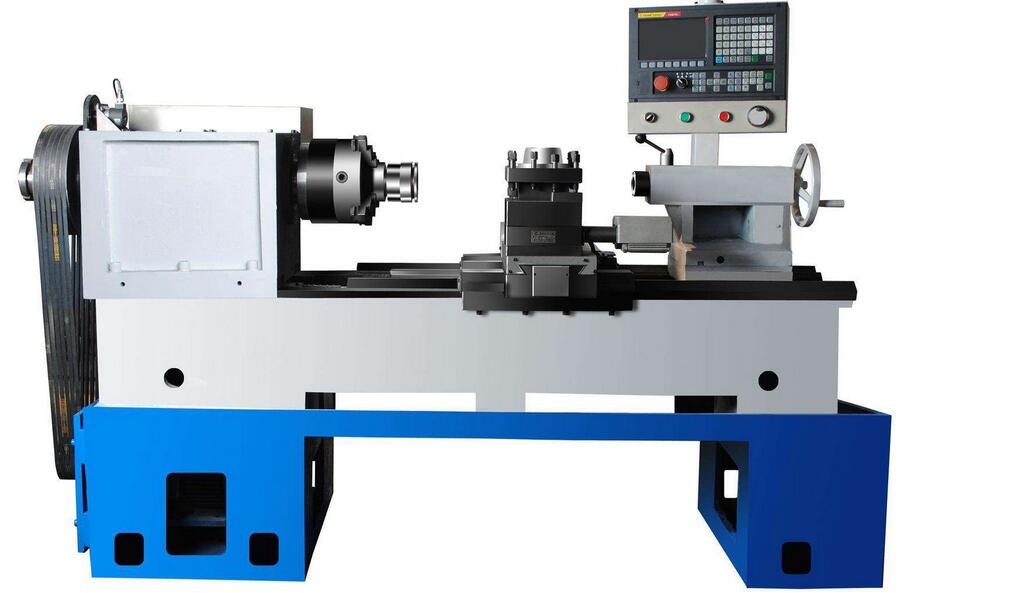

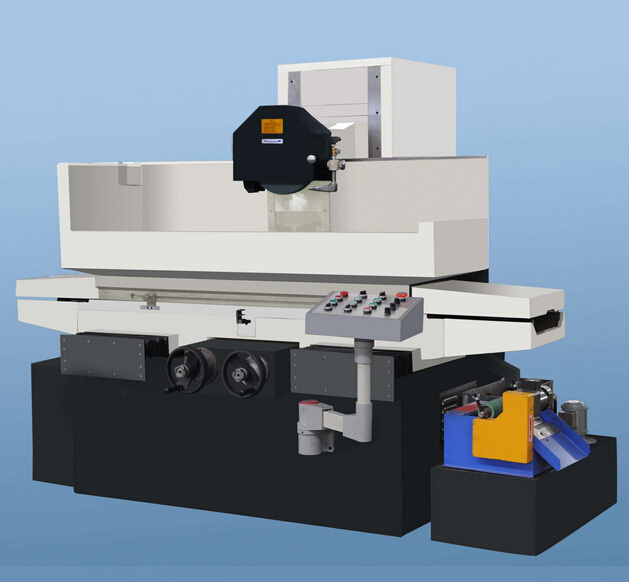

A machine tool is a machine that processes metal blanks into machine parts. It is a machine that manufactures machines, so it is also called a mother machine or a "tool machine". There are many methods for processing mechanical parts in modern machinery manufacturing: in addition to cutting, there are casting, forging, welding, stamping, extrusion, etc., but all parts with high precision requirements and fine surface roughness requirements are generally required. The final machining is carried out by cutting on the machine. In the general machine manufacturing, the processing load of the machine tool accounts for 40%-60% of the total manufacturing work of the machine, and the machine tool plays a major role in the modernization of the national economy. As a new technology, CNC machine tools is the abbreviation of Computer numerical control machine tools, which is an automatic machine tool with a program control system. The control system is capable of logically processing a program having control code or other symbolic instruction specifications, decodes it, and uses a coded digital representation to input the numerical control device through the information carrier. Through the arithmetic processing, various control signals are issued by the numerical control device to control the movement of the machine tool, and the parts are automatically processed according to the shape and size required by the drawings.

CNC machine tools are innovations on the original machine tools. Compared with the original machine tools, they have made greater breakthroughs and advancements, with more accurate precision and higher safety performance. However, the application of CNC machine tools has always been a problem worth exploring. Because the price of CNC machine tools is very high, the cost of CNC machine tools is expensive, the minimum is hundreds of thousands, and the highest is tens of millions. The role of CNC machine tools is very large, and it is the most important one in the production of enterprises. Technology and equipment, if it suddenly fails, huge losses will accompany it. However, at this stage, people only pay more attention to the performance of a piece of equipment, only use it, and pay little attention to the maintenance of the machine. This article will analyze the problems of CNC machine tools in recent years and find out the methods of maintenance and preventive measures.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite