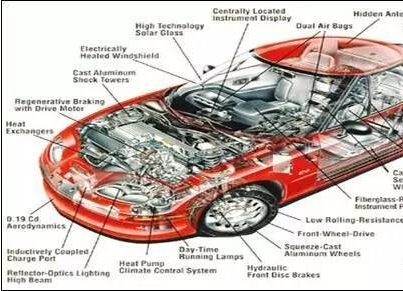

The announcement of the introduction of electric vehicles (EVs) has swept the world. The eye-catching point and difference of these titles is that the electric vehicle's long-range driving capability exceeds the current range of 200 to 300 miles: At present, electric vehicles are comparable to those based on internal combustion engines under all driving conditions and conditions.

A key factor in the success of electric vehicles is consumer acceptance. Due to the decline in the price of lithium batteries and the short-term regulatory support in various regions, consumers expect the price of electric vehicles to decline, so they are not worried about the price. However, they are more concerned about whether the charging speed is faster, or whether the charging time is reduced. Consumers who are used to filling up the fuel tank in a few minutes will have the patience to wait for charging?

ICE vehicles are less than five minutes full of fuel consumption, while electric vehicles fill the battery pack significantly longer. Moreover, the number of charging posts is scarce, which means that consumers may even need to queue up for charging, making charging take longer.

How can I improve the electric car so that it can be quickly charged? Efficient power transfer and higher power levels are a way to improve the speed of on-board and off-board charging. Usually the battery is charged using a constant current method to avoid damage. Based on regional restrictions, increasing the current is neither advantageous nor allowed. In addition, increasing the current can cause wire harness problems, which in turn increases the weight of the vehicle.

Increasing the voltage to 400V or higher is a viable solution. Silicon-silicon (SiC), a wide-bandgap solution for power electronics, delivers power efficiently at high voltages.

SiC is a wide bandgap semiconductor that has become a subversive alternative to silicon-based power switches (metal oxide semiconductor field effect transistor MOSFETs and insulated gate bipolar transistor IGBTs). With the help of low losses (increased efficiency) and high voltage capability, many automotive manufacturers and charger suppliers have adopted SiC. Therefore, with the increase in battery voltage of pure electric vehicles (BEV) (400V and above) and the increase in power level (>10kW) of on-board chargers and off-board DC chargers (50kW and above), SiC is used as electronic power. The switch will become more and more important.

Compared to silicon, SiC has excellent material properties, including low on-resistance, high thermal conductivity, high breakdown voltage, and high saturation speed, enabling low loss and high voltage operation.

It is also important to understand how to drive SiC electronics. The controller indicates that the switch for effective power transfer on the power electronic circuit is turned "on" and "off". The gate driver acts as a key component of the interface between the controller and the power device and acts as an amplifier that receives the controller signal and amplifies the signal to drive the power device.

Due to the superior characteristics of SiCFETs, how to define gate driver requirements becomes critical because these requirements are different from those required to drive silicon MOSFETs or IGBTs.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite