Electricians, inevitably have to deal with a variety of electric motors, the most common are asynchronous AC motors used as power, DC motors, they mainly convert electrical energy into kinetic energy, often called power motors. However, in actual work, you will notice that there are many types of electric motors, some of which are supplemented by power, and the conversion control signals are mainly used. This can meet various precise controls required in production. If you use ordinary motors directly, The control precision can not be guaranteed, can not meet the precision standards required for production. The textile industry needs some precise control because the fabric weaving process requires some control motors. Here I will summarize the various control motors that I have encountered.

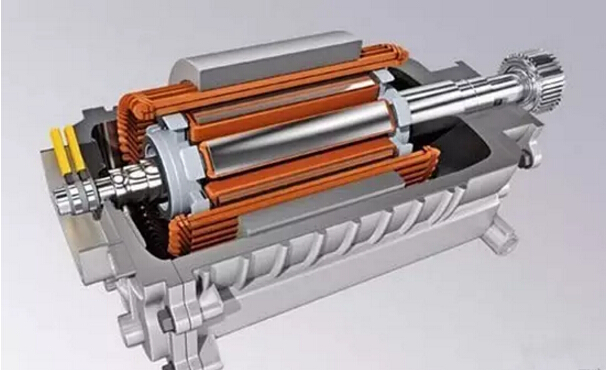

First of all, servo motor, this is more common, usually we also call the implementation of the motor, so the name is still relatively image, it is used together with the servo package, in order to play its powerful functions, there are AC servo motor, there is also DC servo motor, it can The input voltage signal is accurately converted into how much rotation is needed to drive the control object.

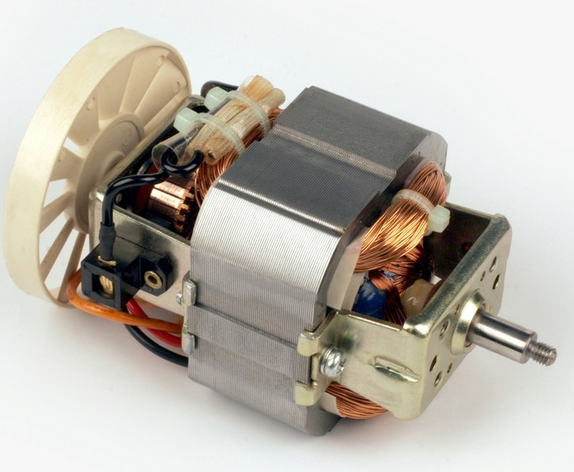

The second category, speed measuring motor, not only the textile industry needs to change the speed of the equipment according to the raw materials and actual conditions, other industries are similar, on the one hand to improve production efficiency, on the other hand to ensure product quality, which sometimes uses speed measuring motor, It is often used in automatic control systems to measure the speed of the equipment and provide the control system with a signal voltage proportional to the speed of the equipment. This type of motor is confusing. It has the appearance of the motor but is not powered. Equipment.

Finally, let's talk about stepping motors. For example, sometimes the distance that the device needs to move a fiber is as high as the thickness of the hair, which requires high precision. The stepper motor has an advantage, it can accurately convert a pulse signal. For line displacement and angular displacement. Its characteristic is: an electric pulse, you can control the motor to rotate a certain angle, drive the machine to move a small distance, control the frequency of the pulse, control the speed of the motor, change the order of the pulse, and change the direction of the rotation.

As a equipment maintenance electrician, it is not necessary to repair all kinds of electric motors, but at least to know its general principle and use, it has a certain guiding role in repairing circuits containing these types of motors.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite