In today's society, people pay more and more attention to environmental protection, and the establishment of an environment-friendly society has been put on the agenda of the government. This is a social form in which people and nature live in harmony. The core connotation is the coordinated and sustainable development of human production and consumption activities and natural ecosystems. Environmentally friendly technologies, environmentally friendly products, environmentally friendly companies, and environmentally friendly industries are part of an environmentally friendly society.

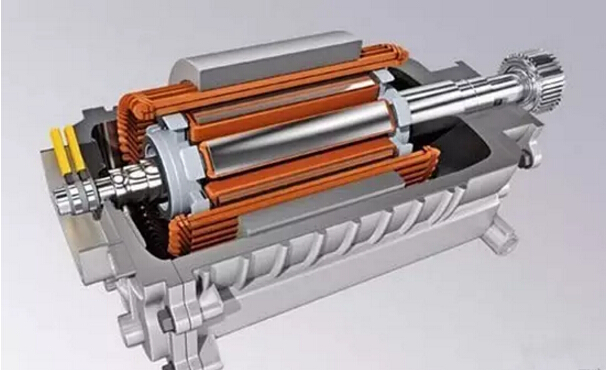

The reducer is a power transmission mechanism that uses a gear speed converter to decelerate the number of revolutions of the motor (motor) to a desired number of revolutions and obtain a mechanism for a large torque. In the current mechanisms for transmitting power and motion, the range of applications of the reducer is quite extensive. The noise pollution of the reducer is also a major factor that damages the environment, which will hinder people from rest, study and work. The low-noise deceleration mechanism should be the subject of research and development by our deceleration machine enterprises.

Reducing the gear transmission noise during the operation of the reducer is an important research topic in the industry. Many scholars at home and abroad regard the change of gear tooth stiffness in gear transmission as the main factor of gear dynamic load, vibration and noise. The shape modification method is used to minimize the dynamic load and speed fluctuations to achieve the purpose of reducing noise. This method has proved to be a more effective method in practice. However, with this method, the process needs to have a shape-cutting device, and the majority of small and medium-sized factories are often unable to implement it.

The noise of the reducer has a great influence on the smoothness of the work, the contact accuracy of the gear, the motion accuracy of the gear, and the assembly accuracy. To reduce the noise of the reducer, it is necessary to know the cause of the noise. The noise is caused by the vibration caused by the action of the periodic alternating force on the bearing and the casing during the operation of the internal gear.

After years of research, it is proposed to optimize the gear parameters, such as the displacement coefficient, the tooth height coefficient, the pressure angle and the center distance, to minimize the impact velocity, and the ratio of the impact velocity to the impact velocity is at a certain value. The range, the gear design method that reduces or avoids the impact of the pitch circle, can also significantly reduce the gear noise.

China Reducer Network believes that with the continuous improvement of processing and manufacturing technology, the development and implementation of advanced assembly technology, and the strict implementation of national and international standards, it will certainly improve the quality of the reducer and reduce the noise of the reducer. This is not only a responsibility that enterprises should undertake for an environment-friendly society, but also an inevitable need of the background of the times. Low-noise reducers will surely gain a place in future industrial manufacturing, bringing real economic benefits to our gearbox companies.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite