1. Analysis of three reasons for electrical misoperation

1.1 operational personnel

(1) The order is incorrect. When you pick up the order, you can't listen to it and one person picks up one person to listen, or ask questions when you pick up the order and don't check it. This is the direct source of misoperation.

(2) Operation ticket problem. There are mainly the following aspects: 1) No ticket operation, the operating personnel think that they have experience or simple operation and do not fill in the operation ticket or replenish the ticket after the operation. 2) If the operation ticket is not correctly filled out, the operation item is not carefully checked but the typical operation ticket is relied on. The problem in the operation ticket is not found, and the operation ticket is considered to be correct. 3) If the ticket is not carefully examined, the guardian does not seriously examine the ticket, resulting in an incorrect operation ticket.

(3) Operational monitoring problems. In the actual operation, the operator will have a dependence on the guardian in business or psychologically. When the operation is performed, the double number of the equipment is not checked, and the error interval is not found. The operation item is not found to be inconsistent with the actual equipment, and the ticket is not carefully recorded. Rehabilitation, causing jump or missed items operation, incorrect operation method, no operation monitoring system, loss of monitoring during operation, negligence of operation, no rules, habitual violations. The so-called habitual violations refer to those behaviors that stick to the old bad habits and work habits and violate the "Electricity Safety Work Regulations". People who are habitually violating the rules, do not follow the rules, often have a chance to turn a blind eye to the dangers in the operation, listen to the inconsistency, and take risks, so that the dangerous point will eventually lead to an accident.

(4) Psychological status problems. The performance is: poor security awareness, people are absent-minded, work responsibility is not strong, and emotions are unstable. Operators who have luck, psychology, ignorance, risk-taking, paralysis, etc., will lead to misuse.

(5) Mental state problems. Some problems in family or work and life have an impact on work, poor mental state, unstable mind, poor health, low mood, listlessness, or psychological defects, personality reasons, etc., can lead to misuse.

In addition, when the shift is handled, there will be a phenomenon in which the shifting personnel push each other, which may cause misoperation. If the shift staff is operating, because the shift staff is eager to get off work, I want to hurry up, I am eager to make progress, and I can't keep up with my energy. I often worry about trouble, simplify the operation procedure, do not follow the procedure, and be alert to the accident. Relaxation, if the guardianship is not effective at this time, it is easy to cause misoperation; if it is operated by the successor, the successor can not enter the role immediately, and the preparation for the operation is insufficient, and the danger is also likely to occur.

1.2 Equipment aspects

(1) The electrical equipment itself is defective. The function of the anti-misoperation locking device of the electrical equipment is not perfect or the function of the anti-missing device is malfunctioning. In actual operation, although there is an anti-misoperation locking device, the function of preventing misoperation is not obtained. The mechanical lockout of the equipment is improperly damaged or rusted, which affects normal use. It is necessary to remove the lock frequently to operate.

(2) Unauthorized use of the unlocking key and unauthorized removal of the locking device. The operating personnel do not master the performance, structure and principle of the anti-misoperation locking device. When encountering emergency operation tasks, the operating system does not perform the relevant procedures and directly uses the unlocking key.

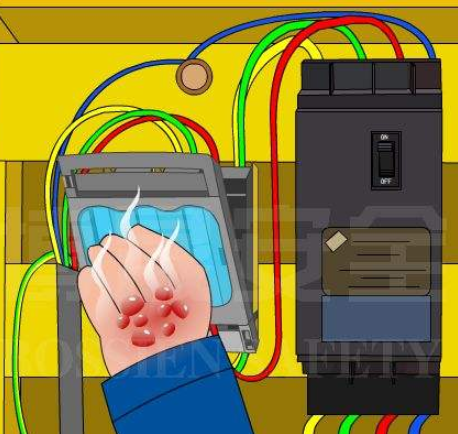

(3) The safety appliance is unqualified. If the insulating gloves are damaged, the electroscope is faulty, the helmet is unqualified, the ladder used is hidden, the insulation strength of the operating rod is not enough, the ladder is not pulled, etc., which are all dangerous points, which will cause misoperation and will constitute personal safety. Threat.

1.3 Environmental aspects

(1) Operation under abnormal weather conditions. The following rain, wind, snow, etc. When operating in snowy days, the operator is prone to slipping under the feet; when operating in rainy days, there is no protective cover for the insulating rod, and the operation ticket is easy to get wet; when the windy day is operated, it will affect people's emotions. These will affect the quality of the operation, so you must pay attention.

(2) When night shift operation, insufficient lighting, people's attention, etc. will affect the quality of operation.

2. Preventive measures against electrical misoperation

2.1 Strengthen technical training and strictly implement standardized operations

(1) "Electricity Safety Work Regulations" is a summary of accident lessons and anti-accident experience. Therefore, it is necessary to carry out dangerous point analysis in strict accordance with the "Electricity Safety Work Regulations", strictly implement the "Electricity Safety Work Regulations", and strictly enforce the basis. Electrical work tickets and operating ticket management systems developed for the actual situation of electrical systems and equipment.

(2) Strictly implement the operation and guardianship system and adhere to the system of ticket re-examination. The operator and guardian must have the appropriate technical qualifications. At least two people must participate in the electrical operation. One person operates and one person monitors; the operator must wear gloves, wear protective clothing and protective masks; the guardian stands on the side of the operated equipment, and The operator maintains an appropriate distance. Pay attention to the operation method, pay attention to the weather and eliminate the dependence.

(3) Before operation and during operation: It is necessary to check whether the operation ticket is consistent with the actual operation task and the system operation mode and equipment operation status at that time. Operators and guardians must maintain a clear mind, high concentration of attention, strong sense of security and self-protection, enhance job responsibility, strictly perform job duties, and eliminate habitual violations.

(4) The operator must carefully check the device name and number before the operation and check the switch status. If the switch is in position, it must be considered and clarified: whether the wrong interval is taken; whether the wrong command is made; whether the equipment has not been stopped. Be sure to check that the switchgear door is normally open and closed, the drawer is pushed and pulled in place, the mechanical lock is normal, and the phase separation plate of the fuse is intact. Before opening the cabinet door, confirm that the isolation switch inside the switch is disconnected.

(5) There must be a written contact list for the stop and power transmission operations. All equipment for stopping and transmitting power must be recorded on the record book. There must be no omissions, especially for the operation of the grounding wire or grounding knife. To be complete and corresponding, there must be no omissions. Be sure to check the grounding knife (wire) before any power supply operation, and confirm that the grounding knife has been disconnected (the grounding wire has been removed) to send power.

(6) Before the power transmission operation, the motor must be tested for insulation. The insurance value must be checked correctly. Any equipment that has been repaired must be inspected locally. Check if the motor is connected to the line, whether the motor is wet or damaged, and if there is any doubt, it cannot be powered. During the power transmission process, if it is found that there is a nameplate on the equipment, it is necessary to find out whether the equipment belongs to the equipment being repaired, or if the maintenance work is completed and the removal measures are forgotten, it must be asked before operation.

(7) Strictly implement the regular rotation system of electrical equipment, strictly implement the periodic test system for electrical equipment, strictly enforce the relevant provisions on electrical equipment insulation testing, and strictly enforce the relevant provisions on electrical equipment inspection.

2.2 Strengthen equipment management and improve equipment reliability

Select stainless steel cable joints with high reliability and reasonable design of switches and equipment with anti-missing locking device, which is convenient for operation personnel and easy for maintenance. Regular tests, strict monitoring and control of the entire operation process. Establish a sound accident key use and storage system, strengthen the electrical personnel's understanding of the performance and structure of the equipment, master the correct use methods, and improve operational skills. Strengthen the inspection and maintenance of safety tools to ensure that they are in good condition.

2.3 Establish a "controllable" thinking and strengthen control over violations

Modern safety management theory believes that although the occurrence of production accidents has its suddenness and contingency, the accident is

Can be predicted, prevented and controlled. We must establish a "controllable" safety guiding ideology. The main cause of misuse accidents is violation of regulations. Anti-violation violations must play the role of safety assurance system and safety supervision system, adhere to people-oriented, base on changing people's abnormal behaviors, implement safety prevention, and control excessive violations. It is necessary to analyze the direct and indirect causes of violations in depth and accurately, and to prescribe the right medicine.

3. Conclusion

In summary, the correctness of electrical operation is an important part of ensuring the safe and reliable operation of the unit equipment. Electrical misoperation can lead to the occurrence or expansion of accidents, thus enhancing the awareness of the electrical operators of danger, overcoming paralysis and preventing risk-taking behavior, thus making the prevention measures more targeted and time-sensitive. Preventing electrical misuse is a long-term and meticulous work. As long as we adhere to the management philosophy of "specialize the symptoms and treat people, people-oriented", we will create a good safety culture atmosphere within the enterprise, and the operational personnel, technicians and management personnel will implement the post responsibility system at all levels. It is no longer difficult to do an accident plan to prevent electrical misuse.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite