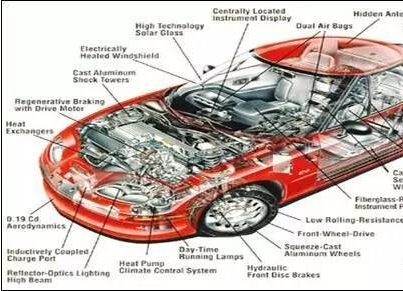

Hub motors have many advantages. Vehicles with hub motors can eliminate the need for transmission components such as clutch assemblies, transmissions, differentials, rear axles, and drive shafts. The most typical are electric motorcycles and ordinary motorcycles. Electric motor directly drives the wheel by the motor, which not only saves the internal combustion engine, but also does not have a gearbox. The chain is reduced by the drive wheel and the motor directly drives the wheel.

The hub motor saves a lot of space while saving some space, which reduces the vehicle's own weight, and the transmission efficiency is also high! And the four wheels are independently controlled, and the wheel differential can be easily realized by electronic control. Features without the need for a mechanical differential. But the advantages of hub motors are so many. Why aren't they used in large quantities on electric vehicles?

First of all, the size of the hub motor itself is large (heavy). As can be seen from the above figure, the hub motor has a lot more than the ordinary car wheel, and the motor quality is the largest.

The finished wheel hub motor has a mass of more than 30kg, and the overweight wheels require higher suspension systems. Engineers of traditional car manufacturers racked their brains to reduce the unsprung mass with lightweight materials. According to the study, the unsprung mass reduction of 1 kg is equivalent to reducing the 15 kg sprung mass.

The unsprung mass has a great relationship with the acceleration, handling and stability of the car, so engineers are trying to reduce the quality of the unsprung, and the quality of the unsprung mass of the electric wheel hub motor suddenly increases the weight by several tens of kilograms. The engineer’s intention is the opposite. However, the daily use of household vehicles, the handling requirements can be reduced, after all, we do not go racing.

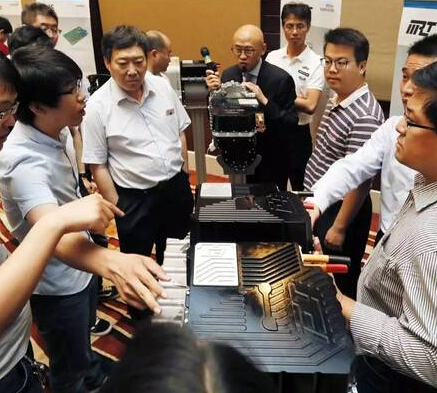

Life problem. The permanent magnet material may demagnetize at high temperatures, and the performance of the motor will degrade after demagnetization. In the driving, the temperature of the brake pads can reach more than 200 degrees. How to solve the heat dissipation perfectly is a problem. In addition, the cost will be relatively high, and mature and stable electronic control technology will take some time to accumulate.

The motor, the controller, the cooling system, etc. are all inherited in a small space, and the wheel usually works in a harsh environment, and the requirements for the tightness, heat dissipation, corrosion resistance, heat dissipation and stability of the hub motor are high. These seemingly simple technologies are also a simple technology for mature applications. At present, BYD K9 (electric bus) has adopted hub motors, and FAW has also developed a chassis for passenger hub motors. I believe that the hub motors will shine in the near future. !

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite