To understand the power performance of a car, you must first know which engine the car is equipped with because the engine is the heart of the car. So for an electric car, its heart is the drive motor. When we look at the information about the powertrain of most electric vehicles, there is a term with a very high frequency, which is a permanent magnet synchronous motor. The reason is that most of the pure electric vehicles in China currently use this type of electric motor as the power source.

Is it now that new energy passenger cars only use permanent magnet synchronous motors? In fact, some medium and high-end pure electric vehicles will choose to use AC asynchronous motors, such as Tesla and Weilai. In addition, the Audi e-tron and the Beijing Benz EQC, which will be launched in China, are also equipped with two AC asynchronous motors for the front and rear axles. Compared with the permanent magnet synchronous motor used in the domestic mainstream electric vehicles, the asynchronous motor used in the middle and high-end electric vehicles with higher price and higher positioning is more advanced?

Where are the differences between the two types, and what are the advantages?

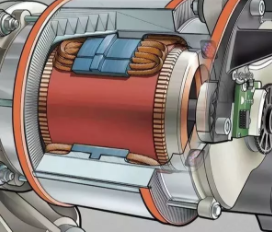

The working principle of the motor is that the energized coil is subjected to a force in a changing magnetic field, and the two magnetic fields interact to generate electromagnetic torque to be converted into kinetic energy to drive the vehicle. Here, the way in which the magnetic field is generated is different, and an alternating current asynchronous motor and a permanent magnet synchronous motor are formed.

The biggest advantage of permanent magnet synchronous motors is their very high power density and torque density, and lower energy consumption. At the same weight and volume, permanent magnet synchronous motors can output higher power and torque. By the same token, with the same power and torque, the permanent magnet synchronous motor can achieve the minimum weight and volume, leaving enough space and quality for another extremely important component "power battery". The disadvantage is that the price of the permanent magnet material required for the motor is high, thereby increasing the manufacturing cost of the motor and even the entire vehicle.

The biggest advantage of permanent magnet synchronous motors is their very high power density and torque density, and lower energy consumption. At the same weight and volume, permanent magnet synchronous motors can output higher power and torque. By the same token, with the same power and torque, the permanent magnet synchronous motor can achieve the minimum weight and volume, leaving enough space and quality for another extremely important component "power battery". The disadvantage is that the price of the permanent magnet material required for the motor is high, thereby increasing the manufacturing cost of the motor and even the entire vehicle.

The advantages and disadvantages of AC asynchronous motors are just the opposite of those of permanent magnet synchronous motors. The former has the advantage that it does not require expensive permanent magnet materials for manufacturing motors, so the cost is lower, the process is simple, the operation is reliable, the maintenance is convenient, and the complex working environment can be used. The middle work also has a strong adaptability to the large changes in the surrounding working temperature. The disadvantage is that under the same power and torque, the volume and weight of the asynchronous motor is much larger than that of the permanent magnet synchronous motor, and the energy consumption is relatively higher.

The advantages and disadvantages of AC asynchronous motors are just the opposite of those of permanent magnet synchronous motors. The former has the advantage that it does not require expensive permanent magnet materials for manufacturing motors, so the cost is lower, the process is simple, the operation is reliable, the maintenance is convenient, and the complex working environment can be used. The middle work also has a strong adaptability to the large changes in the surrounding working temperature. The disadvantage is that under the same power and torque, the volume and weight of the asynchronous motor is much larger than that of the permanent magnet synchronous motor, and the energy consumption is relatively higher.

Different choices of domestic and foreign car companies have their own considerations

In fact, the two types of motors have different lengths, which does not mean that AC asynchronous motors are more advanced than permanent magnet synchronous motors. The cost of the permanent magnet module is relatively high, but the rare earth raw material for making permanent magnets is rich in domestic reserves, and to some extent, the manufacturing cost of the domestic permanent magnet synchronous motor is also reduced. The national policy promotes the “daytime” of the development of new energy vehicles, the “land advantage” created by the advantages of local resources, and the “human harmony” created by domestic consumers’ demand for large space and low energy consumption. Three key factors have prompted most domestic car companies to choose Permanent magnet synchronous motor.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite