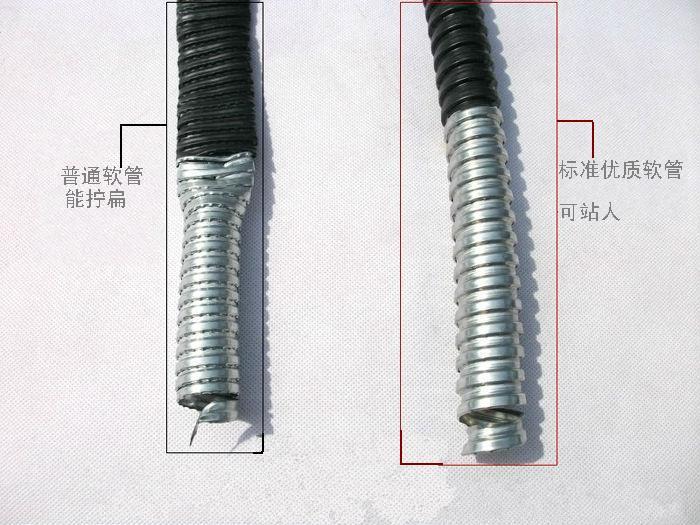

Plastic coated metal hoses are widely used in electric power, chemical, metallurgy, light industry, machinery and other industries. They are coated on the wall of stainless steel hoses and galvanized metal hoses along the concave and convex surface of the core of the tube wall. The layer cable is made of polyvinyl chloride material. Because the plastic coated metal hose is light in weight, excellent in flexibility, connection strength with accessories, electrical performance and oil resistance, splash resistance and the like.

Plastic coated metal hoses are widely used in electric power, chemical, metallurgy, light industry, machinery and other industries. They are coated on the wall of stainless steel hoses and galvanized metal hoses along the concave and convex surface of the core of the tube wall. The layer cable is made of polyvinyl chloride material. Because the plastic coated metal hose is light in weight, excellent in flexibility, connection strength with accessories, electrical performance and oil resistance, splash resistance and the like.However, the plastic coated metal hose connector is used to realize the quick release of the hose and the field device, but the existing plastic coated metal hose connector is only suitable for the plastic coated metal hose with a relatively regular connection connector, due to the needs of the enterprise equipment. Regular and irregular maintenance and repairs require the disassembly and assembly of the plastic-clad metal hoses. When disassembling, the joints are often irregular, which makes the joints not tightly connected with the plastic-coated metal hoses. After that, there will be three scattered parts, which are easy to lose chaos and have low installation efficiency.

Further improvement of the defects of the prior art can provide a simple structure, convenient use, quick release and quick installation of the hose and the field device, improve efficiency, keep the field equipment neat and beautiful, and prevent water splashing through the cable hole into the device. A plastic metal hose quick connector.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite