my country is a big industrial country, and the upgrading of industrial intelligence not only implements the national strategy but also conforms to the development trend of the times. However, enterprises in the industrial manufacturing field generally have challenges such as weak technical foundation, difficult data collection, diverse scene requirements, and complex deployment environments, which limit the pace of intelligent upgrading of enterprises. As a leading AI company with a strong Internet foundation, Baidu has been actively promoting the innovative application of AI technology in the industrial field.

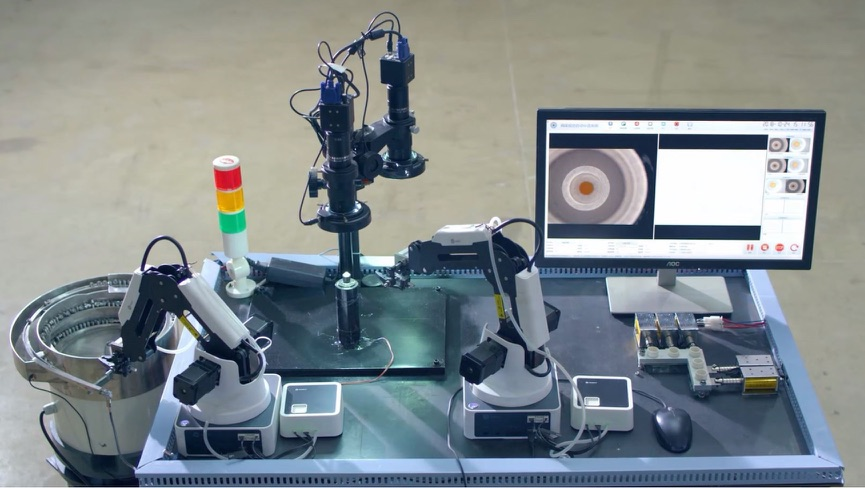

Intelligent detection equipment for injector valve seat defects

Made in China, quality first. Industrial quality inspection is one of the most important links in industrial production and an important breakthrough in industrial transformation and upgrading. Traditional industrial quality inspection relies on manpower, which is not only low in efficiency and high in error rate, but also high in manpower costs, and personnel are easily lost. The industrial vision intelligence platform of Baidu Smart Cloud "Cloud Intelligence Integrated" replaces manual quality inspection with machine vision quality inspection, which realizes rapid and accurate identification and classification of product defects. According to the China Industrial Quality Inspection Report released by the global authoritative consulting organization IDC in August this year, Baidu Smart Cloud ranked first in market share.

Since 2017, Baidu AI quality inspection has been implemented in more than ten industries such as 3C, automobile, steel, textile, etc., serving Shougang, Baowu, Hengyi, FAW and other enterprises. As a leading enterprise in China's chemical fiber industry, Hengyi Petrochemical has changed the traditional quality inspection mode that relied on human eyes + flashlight with Baidu Smart Cloud intelligent quality inspection system, and greatly improved the quality inspection efficiency; FAW Logistics is a professional logistics company under the FAW Group , In order to improve the efficiency of vehicle inventory, Baidu Smart Cloud’s vision technology has realized the drone inventory of automobiles, which has shortened the time by 80% compared with manual labor; Liuzhou Yuanchuang is the only company in the country that can support the injection Oiler companies use Baidu Feidao Enterprise Edition EasyDL zero threshold AI development platform to train and deploy an injector valve seat defect detection model with a recognition rate of 95%, saving nearly 600,000 manpower costs every year.

The technology base for Baidu to help enterprises realize intelligent quality inspection is the flying paddle deep learning platform. Flying Oar is a self-developed open source, open, feature-rich, industrial-grade deep learning platform that provides developers with basic core frameworks, model libraries, development kits, tool components, as well as EasyDL and BML, a visual development platform for the enterprise version of Flying Oar. Significantly lower the threshold for AI application development. Currently, Flying Paddle has gathered more than 3.6 million developers from all walks of life, developed 400,000 AI models, served 130,000 enterprises and institutions in total, and helped developers use AI technology quickly and efficiently. Based on the flying paddle platform, Baidu can provide data enhancement tools, high-quality open source models, industrial-grade deployment and other capabilities to help industrial companies solve the pain points of data lack, reduce model deployment costs, and improve the efficiency and accuracy of defect detection.

Vision technology is the core technology of AI quality inspection. Baidu has created a visual intelligence solution that integrates software and hardware. In terms of software, Baidu provides developers with a fully closed-loop service process from data collection, sample labeling, model training, and model deployment based on the flying paddle. In terms of hardware, Baidu provides smart face video analysis boxes, production safety monitoring analysis boxes and other equipment to carry AI applications. The integration of software and hardware fully assists the application of AI technology in industrial quality inspection scenarios, and accelerates the development of industrial intelligence.

Industrial intelligent upgrading is an important opportunity for my country's industry to "change lanes and overtake", and it is also an important means for my country to transform from a manufacturing power to a manufacturing power. The intelligence of quality inspection scenes can not only improve industrial production efficiency and reduce labor costs, but it is also an important step in the upgrade of industrial intelligence. Baidu builds smart industrial solutions based on flying propellers, provides safe and controllable industrial intelligent infrastructure for industrial development, accelerates the integration and innovation of traditional industries and new-generation information technology, and helps companies reduce costs and increase efficiency, green double carbon, and smart upgrades. Leading technological innovation and application will determine the height of China's participation in global manufacturing competition.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite