Lithium battery main anode materials are tin-based materials, lithium-based materials, lithium titanate, carbon nano-materials, graphene materials. Lithium battery anode material energy density is one of the main factors affecting the energy density of lithium batteries, lithium battery cathode material, anode material, electrolyte, diaphragm is called lithium battery four core materials. Here we briefly introduce the various types of negative electrode material performance indicators, advantages and disadvantages and possible improvement direction.

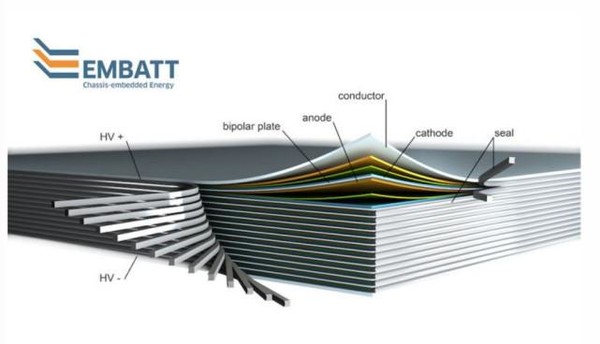

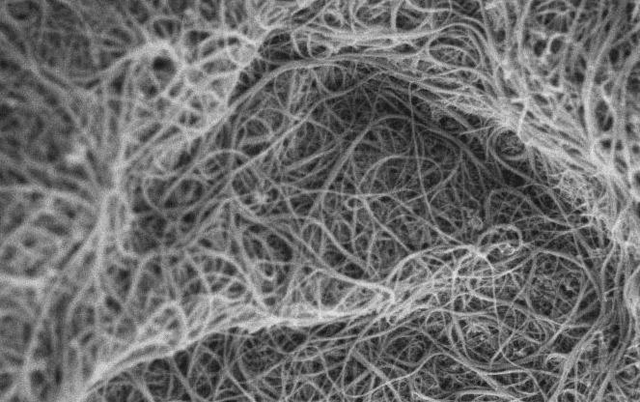

Carbon nanotubes

Carbon nanotubes are a graphitized carbon material with excellent electrical conductivity. At the same time, because of its small depth of intercalation of lithium, the stroke is short, as the anode material in the large magnification charge and discharge polarization is small, can improve Battery charge and discharge performance.

However, carbon nanotubes directly as lithium battery anode material, there will be irreversible capacity, voltage hysteresis and discharge platform is not obvious and other issues. Such as Ng and so on with a simple filter prepared single-walled carbon nanotubes, as a direct anode material, the first discharge capacity of 1700mAh / g, reversible capacity of only 400mAh / g.

Figure 1 carbon nanotube negative charge

Another application of carbon nanotubes in the negative electrode is to combine with other negative materials (graphite, lithium titanate, tin, silicon, etc.), using its unique hollow structure, high conductivity and large specific surface area as a carrier Improve the electrical properties of other negative materials. The first reversible capacity of 443mAh / g was calculated by chemical vapor deposition (CVD), and the carbon nanotubes were grown in the pores of expanded graphite. The first reversible capacity was 443mAh / g. , The reversible capacity can still reach 259mAh / g. The hollow structure of the carbon nanotubes and the pores of the expanded graphite provide a large amount of lithium active sites, and this structure can cushion the volume effect of the material during charging and discharging.

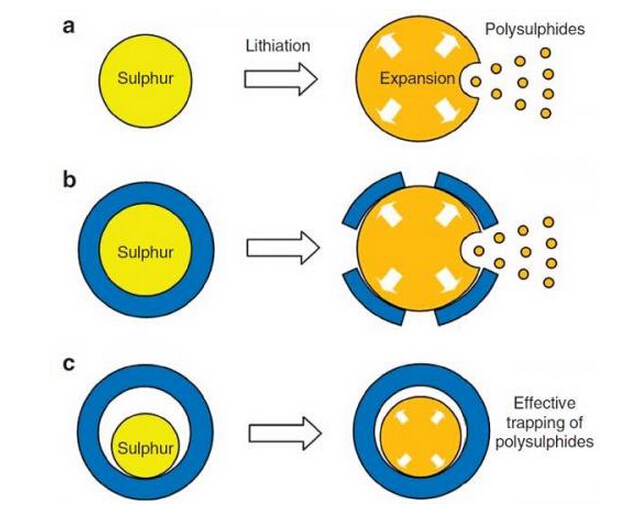

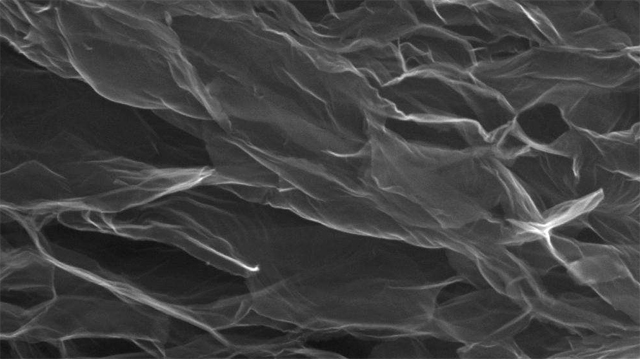

Graphene

In 2004 the British University of Manchester researchers first discovered graphene materials, and won the Nobel Prize. Graphene is a new carbon material formed by carbon six-membered rings with many excellent properties such as large specific surface (about 2600m2g-1), high thermal conductivity (about 5300Wm-1K-1), high electron conductivity ( Electron mobility of 15000cm2V-1s-1) and good mechanical properties, as lithium-ion battery materials and concern.

Graphene directly as a lithium battery anode material, with a very considerable electrochemical performance. In the laboratory, hydrated hydrazine hydrate was used as the reducing agent to prepare the graphene morphology of the jungle, which had both hard and soft carbon properties and showed the characteristics of the capacitor in the voltage range above 0.5V.

Figure 2 graphene anode material

The first reversible capacity of the graphene anode material at the discharge rate of 1C is 650mAh / g, and the capacity after 100 times of charge and discharge cycle can reach 460mAh / g. Graphene can also be used as a conductive agent, combined with other negative materials to improve the electrochemical properties of the anode material. Fe3O4 / graphene composites were prepared by ultrasonic dispersion method. The discharge was carried out at a current density of 200 mA / g. After 50 cycles, the capacity was 1235 mAh / g. The discharge was carried out at a current density of 5000 and 10000 mA / g. After 700 cycles, the capacity can reach 450mAh / g and 315mAh / g, respectively, showing higher capacity and good cycle performance.

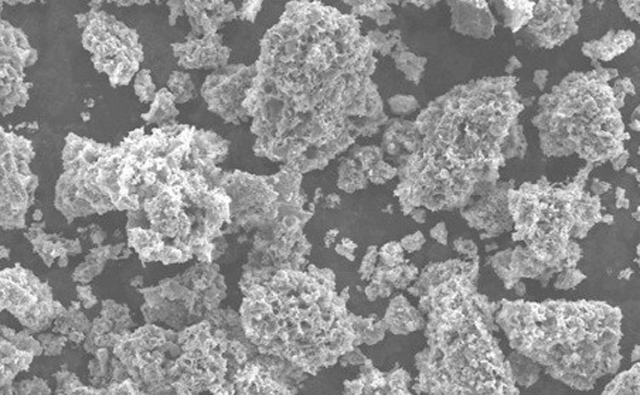

Lithium titanate

Spinel-type lithium titanate is used as a concern anode material, because of the following advantages:

1) Lithium titanate almost "zero strain" (before and after deintercalation of lithium) from 0.836nm to 0.837nm before and after deintercalation of lithium;

2) high lithium intercalation (1.55V), to avoid "lithium dendrite" production, high security;

3) has a very flat voltage platform;

4) Chemical diffusion coefficient and high efficiency of Coulomb.

Lithium titanate has many advantages to determine its excellent cycle performance and high safety, however, its conductivity is not high, large current charge and discharge capacity attenuation is serious, usually using surface modification or doping to improve its conductivity rate. Such as Mg (NO3) 2 as Mg source, Mg2 + doped lithium titanate was prepared by solid phase method, indicating that Mg2 + doped with spinel crystal structure of lithium titanate did not destroy the structure of the spinel crystal The dispersion capacity is better, its specific capacity at the discharge rate of 10C can reach 83.8mAh / g, 2.2 times of the undoped material, and after 10 times the charge and discharge cycle capacity without significant attenuation, the AC impedance test shows that The charge transfer resistance of the miscellaneous material is significantly reduced. Zheng and so on through the high temperature solid phase method, respectively, using Li2CO3 and lithium citrate as lithium source, prepared pure phase of lithium titanate and carbon coated lithium titanate.

Figure 3 Lithium titanate anode material

Experiments show that the carbon-coated lithium titanate has a smaller particle size and good dispersion, showing better electrochemical performance, mainly due to carbon coating to improve the surface of the lithium titanate particles of the electrical conductivity , While the smaller particle size shortens the diffusion path of Li +.

Silicon-based materials

Silicon as a lithium-ion battery ideal anode material, has the following advantages:

1) silicon can form Li4.4Si alloy with lithium, the theoretical capacity of lithium storage up to 4200mAh / g (more than 10 times the specific capacity of graphite);

2) silicon intercalation potential (0.5V) slightly higher than graphite, in the charge is difficult to form "lithium dendrite";

3) silicon and electrolyte reactivity is low, does not occur organic solvent co-embedding phenomenon.

However, the silicon electrode in the charge and discharge process will occur in the cycle performance degradation and capacity attenuation, there are two main reasons:

1) silicon and lithium generated Li4.4Si alloy, the volume expansion of up to 320%, a huge change in volume easily lead to active substances fall off from the current collector, thereby reducing the electrical contact with the collector, resulting in rapid decline in electrode cycle performance;

2) LiPF6 decomposition of the electrolyte generated by the trace of HF will erode silicon, resulting in silicon electrode capacity attenuation.

In order to improve the electrochemical performance of silicon electrodes, there are usually the following ways: the preparation of silicon nanomaterials, alloy materials and composite materials. Such as Ge and other chemical etching method using boron doped silicon nanowires, 2A / g charge and discharge current, the cycle after 250 weeks capacity can still reach 2000mAh / g, showing excellent electrochemical properties, due to The lithium detachment mechanism of silicon nanowires can effectively alleviate the volume expansion during the cycle. Liu et al. Prepared the Si-NiSi-Ni complex by high energy ball milling, and then dissolved the Ni element in the complex with HNO3 to obtain the porous Si-NiSi complex.

By XRD, it is found that NiSi alloy exists in the system, which not only provides the reversible capacity for the negative electrode material, but also cooperates with the pores inside the particle, and the volume expansion of the buffer silicon during the charge and discharge cycle increases the circulation performance of the silicon electrode. Lee and so on. The core-shell Si / C composites were prepared by pyrolysis at 700 ℃ under argon atmosphere. After 10 cycles, the reversible capacity of the composites was 1029mAh / g, indicating that Na2CO3 forms a covalent bond between the silicon surface and the phenolic resin, and then undergoes high temperature cracking to improve the contact between the silicon and the cracked carbon, thereby improving the circulation of the anode material and reducing the irreversible capacity loss.

Tin alloy

SnCoC is a kind of material which is more commercially available in the tin alloy anode material. It can mix Sn, Co and C elements uniformly at the atomic level and not be crystallized. The material can effectively inhibit the electrode during charging and discharging Material volume changes, improve the cycle life. In 2011, Japan SONY announced the use of Sn-based amorphous material for the capacity of 3.5AH 18650 cylindrical battery anode. The theoretical specific capacity of the elemental tin is 994 mAh / g, which can form intermetallic compounds with other metals Li, Si, Co and so on. The Sn-Co alloy with three-dimensional porous structure was prepared by electrodeposition of Sn-Co alloy on the surface of Cu thin film carrier by surface electroless deposition.

The first discharge capacity of the material is 636.3mAh / g, the first Coulomb efficiency is 83.1%, and the specific capacity after 70 cycles is still 511.0mAh / g. Wang and so on with graphite as the dispersant, SnO / SiO and lithium metal mixture as the reactant, using high-energy mechanical ball milling and post-heat treatment, prepared in the graphite matrix uniform dispersion of Sn / Si alloy, the material in the 200 charge and discharge After the cycle, the reversible capacity is still up to 574.1mAh / g, performance is better than the other SnO or SiO and other negative materials.

Tin oxide

SnO2 has attracted much attention because of its high theoretical specific capacity (781mAh / g). However, there are some problems in the application process: the first irreversible capacity is large, and there is a large volume effect when the lithium is intercalated (volume expansion 250 % ~ 300%), the cycle is easy to reunite and so on.

The results show that the agglomeration of SnO2 particles can be effectively suppressed by the preparation of composite materials, and the volume effect of lithium intercalation can be alleviated and the electrochemical stability of SnO2 can be improved. Zhou and so on by chemical deposition and high temperature sintering method to prepare SnO2 / graphite composite material, its 100mA / g current density, the specific capacity of up to 450mAh / g above 2400mA / g current density, the reversible specific capacity of more than 230mAh / g Experiments show that graphite as a carrier can not only disperse SnO2 particles more evenly, but also can effectively inhibit the agglomeration of particles and improve the material circulation stability.

In summary, in recent years, lithium-ion battery anode material toward the high specific capacity, long cycle life and low cost direction. Metal-based (tin-based, silicon-based) materials play a high capacity at the same time with the volume changes, because the metal-based alloy material capacity and volume changes are proportional to the actual cell volume does not allow large changes (generally less than 5% ), So its practical application in the capacity to play a greater limit to solve or improve the volume change effect will become the direction of metal-based materials research and development.

Lithium titanate has the advantages of small volume change, long cycle life and good safety, and has great potential for development in large energy storage fields such as electric vehicles. Because of its low energy density, lithium titanate has the advantages of high voltage cathode material LiMn1.5Ni0 .5O4 match the use of future high-powered battery development direction.

Carbon nanomaterials (carbon nanotubes and graphene) have the advantages of specific surface area, high conductivity, chemical stability and so on. They have potential applications in new lithium ion batteries. However, carbon nanomaterials alone as negative materials exist irreversible capacity, voltage hysteresis and other shortcomings, and other negative material composite use is the more practical choice.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite