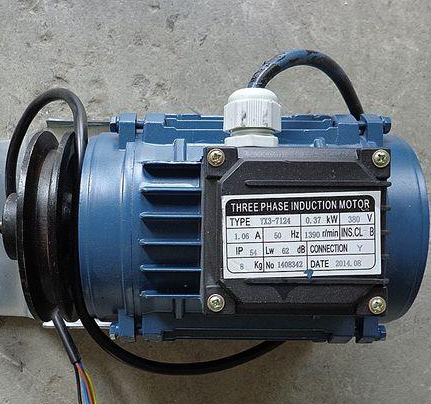

Distribution transformer, referred to as "distribution", refers to the distribution system according to the law of electromagnetic induction conversion AC voltage and current transmission of alternating current energy of a static electrical appliances. Some areas will be 35 kV or less (mostly 10KV and below) voltage level of power transformers, known as the "distribution transformer", referred to as "distribution." Installation of "distribution" of the place and place, both the substation. Distribution transformer should be installed on the column or open-air floor installation. Details of its installation, installation precautions, supply and distribution methods, capacity selection, operation and maintenance.

What are the common faults of distribution transformers?

1. Three-phase load imbalance or seasonal overload

In the rural areas, most of the power load is single-phase load, and the load changes greatly, therefore, there are many distribution transformer three-phase load imbalance, So that the three phases can not run symmetrically, resulting in zero sequence current. This aspect increases the loss of the transformer, on the other hand reduces the effective capacity of the transformer. The above two cases will lead to transformer overheating, insulating oil aging, so that the insulation layer to reduce the level, and ultimately will lead to damage to the transformer. The following measures can be taken:

① Investigation of the load distribution of the transformer, including the load of 24 hours a day and the load of four seasons, clarify the load of the general situation, and try to adjust the three-phase load, so close to the symmetrical operation;

② adjust the power peak time, reduce the overload situation; at the same time to the transformer capacity in time to avoid long-term overload operation of the transformer.

Poor grounding

Lightning protection work is generally done, but there are still two problems: ① arrester grounding bad; ② only pay attention to the high side of the installation of lightning arrester, while ignoring the low side of the need to install the arrester problem (especially Multi-lei area). If the arrester is not properly grounded, when the overvoltage occurs, the arrester can not discharge the current well, it will make the transformer insulation damage; if the low side is not installed arrester, when the high side of the arrester to the earth to release a large lightning current, A voltage drop is generated at the ground position, which is also applied to the neutral point of the low-voltage side winding while the transformer housing is grounded, while the low-voltage side winding is grounded by the wave impedance of the low-voltage line. Can take the following measures [1]:

① to find out with the arrester related to the poor ground, according to the requirements to re-change. Note that the grounding wire of the arrester should be connected directly with the shell of the transformer and the low side of the transformer, and then the grounding device is shared. Its grounding resistance is not more than 4 Ω; ② for the mine area, low-voltage side to add a group of low-voltage arrester.

3. Oil leakage

Transformer oil leakage in the transformer transformer is also more. Due to leakage, so that the oil within the transformer to reduce the oil level, resulting in air and water vapor infiltration, to speed up the oxidation of oil and make it worse, so that the viscosity of the oil becomes larger, convection speed, affecting the transformer heat The temperature rise is high, which further accelerates the deterioration of the oil. While the deterioration of the oil after the acidity of the insulation, resulting in reduced insulation resistance of the winding, and even play a role in the destruction of insulation, the long run, will inevitably lead to transformer damage. Can take the following measures: ① to identify the place where the oil leakage, and make a deal; ② to see whether the transformer oil deterioration deterioration, the oil for a simple analysis. If the transformer oil from the initial yellow light gradually into orange, brown, and the oil viscosity is large, indicating that the transformer oil has deteriorated, it must be purified or replaced; ③ when the transformer oil is not deteriorated deterioration, check the oil level is Too low If too low, then refueling to the transformer oil conservator marking scale; ④ check the winding insulation resistance.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite