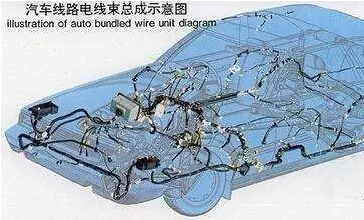

Electronic wiring harness has become the focus of maintenance of the car

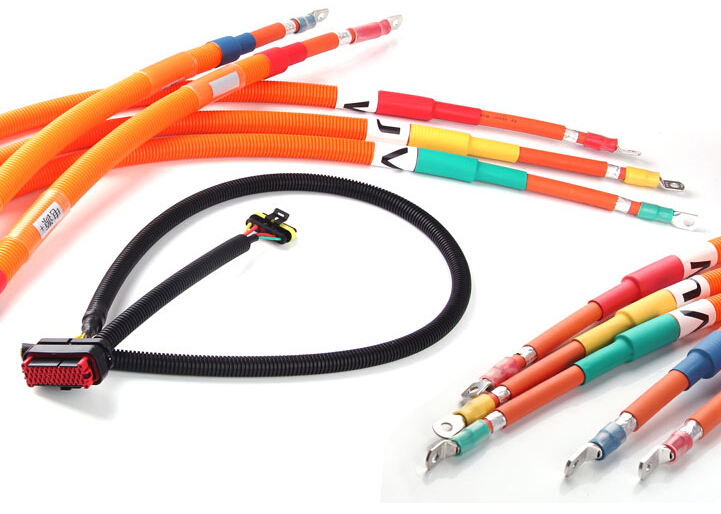

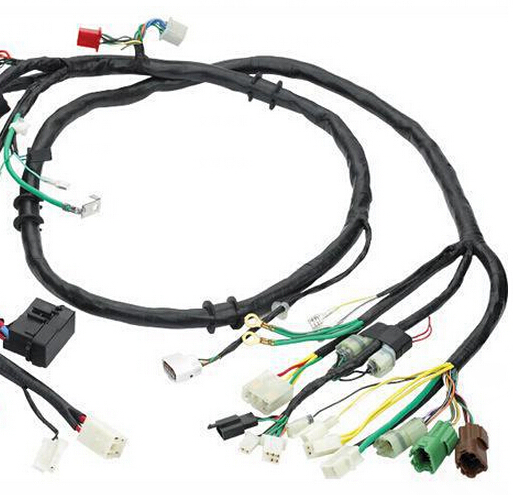

In today's era, the car more and more eccentric development, we can see the important responsibility of automotive electronic wiring harness, a master in the long-term vehicle maintenance practice found that 35% of the car failure is due to electronic wiring harness circuit failure caused, Therefore, the maintenance of vehicle circuit failure is one of the main contents of vehicle maintenance work. In the maintenance of the circuit, the car harness is the focus of maintenance of the object, because many automotive wiring harness circuit failure is often due to electronic wiring harness wire break or aging caused. To this end, the general wiring harness wire can be used to connect the following two methods, one welding, the second is flat joint connection.

Maintenance of automotive wiring harness, connection skills

In the repair of automotive wiring harness welding technology, its operation is simple, fast, in many types of line connections can play a good connection, and only need a small electric iron can be achieved. Usually the wiring harness welding need to pay attention: select the electrode, in the car wiring harness connection, usually choose rosin core solder; to ensure clean and clean welding, no paint, butter, oil and other insulators and other substances, so as not to affect the welding quality; Preheat, the first use of electric soldering iron to get preheated, warm-up time can be a few seconds, and then the electrode melting in the wire connection parts. The so-called flat joint connection technology, that is, do not need to change the physical properties of wires or connectors to achieve the electronic wiring harness connection technology. In the course of the operation need to pay attention: a reasonable choice of wire stripping holes, so as not to damage the wire inside the metal material; and then stripped of the insulator metal material on the need to connect the joint or flat tube, and then use the tie wire tool to firmly Of the tie, the general line of joints tie two fold, flat take over the tube in the four fold; bar after the end of the tape or heat shrink hose to connect the connection to achieve the effect of insulation against oxidation; in order to ensure the life of electronic wiring harness.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite