1, harness wrapping design

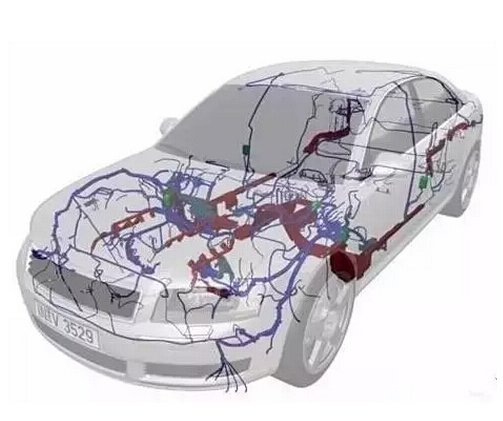

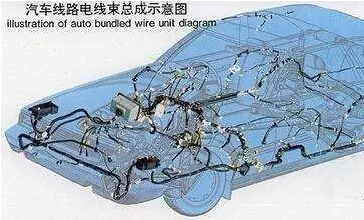

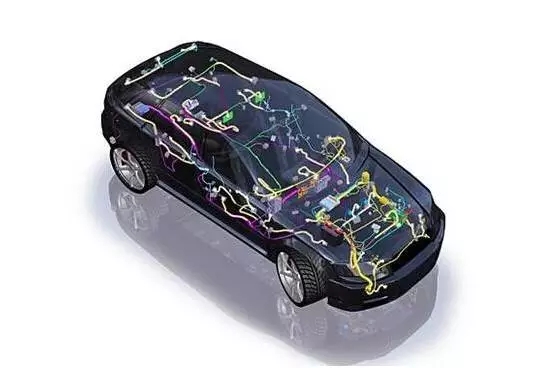

The harness bundles have the functions of wear-resistance, flame-retardant, anti-corrosion, anti-interference, noise reduction, and beautification of the appearance. Generally, the following bandage design schemes are formulated according to the working environment and the size of the space.

Due to the harsh working environment of the engine wiring harness, it is entirely coated with a highly flame-retardant, waterproof, and mechanically strong bellows.

The working environment of the front cabin is also relatively poor. Most of the branches are also wrapped with a good flame-retardant bellows, and some branches are wrapped with PVC tubes.

The instrument line has a small working space and the environment is relatively good. All tapes can be wrapped or twisted.

The door line and the roof line have a small working space, and can be completely wrapped with tape. Some branches can be wrapped with industrial plastic cloth; thinner roof lines can be directly attached to the body with sponge tape.

Because the chassis line has more contact with the vehicle body, it is wrapped with a bellows to prevent the wire harness from wearing.2. Performance analysis of raw materials for dressing

1. Bellows

Corrugated pipe generally accounts for about 60% or even more in the bundle. The main features are good wear resistance, high temperature resistance, flame retardancy, and heat resistance in the high temperature zone. Corrugated pipe temperature resistance between -40-150 °C. Its material is generally divided into PP and PA2 species. PA material is superior to PP material in flame retardancy and abrasion resistance; however, PP material is more resistant to bending fatigue than PA material.

2. PVC pipe

The function of PVC pipe is similar to that of bellows. PVC pipe is better in flexibility and anti-bending deformation, and the PVC pipe is generally closed, so the PVC pipe is mainly used for branching of the wire harness in order to make the wire smoothly transition. PVC pipe heat-resistant temperature is not high, generally below 80 °C.

3. tape

The adhesive tape plays a role in banding, wear resistance, insulation, flame retardance, noise reduction, marking, etc., and generally accounts for about 30% in the packing material. Harness tape is generally divided into PVC tape, air-felt tape and cloth tape. PVC tape wear resistance, flame resistance is good; temperature is about 80 °C, noise reduction is not good, the price is cheaper. The fleece tape and cloth tape material are PET. The velvet cloth tape has the best packing and noise-reducing properties, and the temperature resistance is about 105°C. The cloth tape has the best wear resistance and the maximum temperature resistance is about 150°C. The common disadvantages of fleece and cloth tapes are poor flame

retardancy and high price.

3, wire harness fixed design

The central electrical box is generally fixed with steel strips, bolts, etc., or is directly mounted on the vehicle body with a fixed structure designed by the electrical box itself.

Each wire harness is generally fixed in a body hole with a plastic tie, a hook, or the like. Body holes are mostly round holes or elliptical holes, generally ranging from 5mm, 6mm, and 7mm in diameter.

The butt-joint jackets of various harnesses are generally fixed together with a jacket bracket and installed on the body.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite