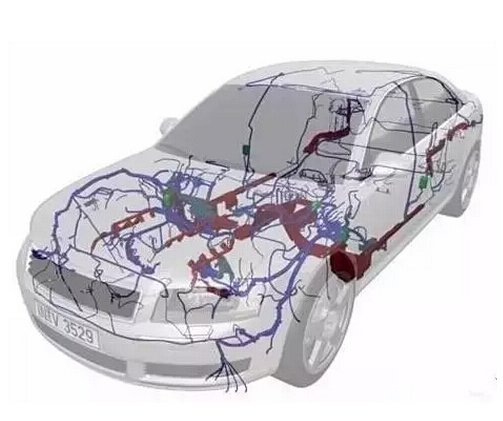

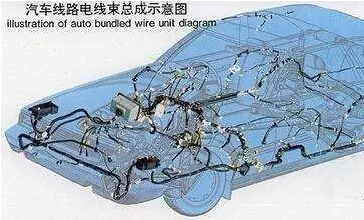

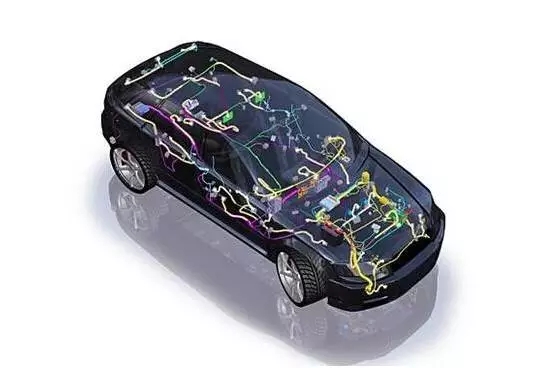

At present, new energy vehicles mainly have two forms of pure electric vehicles and hybrid vehicles. In terms of complete vehicle wiring harness design, it is different from the traditional gasoline vehicle complete vehicle wiring harness, there are high-voltage wiring harnesses and low-voltage wiring harnesses, and wiring harness designs of new energy vehicles of different forms. Uses different forms of design and layout

1, high voltage wire harness design

The high-voltage wire harness mainly provides high-voltage and high-voltage power supply for new energy vehicles. Therefore, it is particularly important for the design and layout of wire harnesses. The following principles are mainly followed:

(1) Cable harness design and wire diameter design: The high-voltage wire harness design adopts a dual-track system. Since the high voltage has exceeded the safety voltage of the human body, the vehicle body cannot be used as the cadastral point of the vehicle. Therefore, on the design of the high-voltage wiring harness system, the DC high-voltage power circuit must be strictly implemented. Double track system. High-voltage wire harnesses can be divided into high-voltage motor lines, high-voltage battery lines, high-voltage charging lines.

(2) Selection of high-voltage connectors: High-voltage connectors are mainly responsible for high-voltage and high-current connection and transmission, and are responsible for the human-machine safety of high-voltage loops. Therefore, high-voltage harness connectors currently use high pressure resistance, high waterproof rating, loop interlock, and shield connection.

(3) Shield design: Shielded high-voltage lines are used, and the shielded network is covered inside the high-voltage line. Shield connection is achieved when the connector is connected. Taking into account the electromagnetic interference factors, the entire high-voltage wiring harness system is completely covered by the shielding layer.

2. Low voltage wiring harness design

(1) Harness direction design and wire diameter design:

(2) Selection of Low Voltage Harness Fixtures:

(3) Shield design:

(4) Low-voltage connector selection: Our new energy vehicle low-voltage harness design scheme continues the traditional vehicle design platform. The low voltage harness satisfies the realization of the traditional car function, and is also responsible for the function realization of the strong electric control unit module. The low-voltage wire harness design and layout plan considers the interference protection produced by the high-voltage wire harness. Different sources use different low-voltage shielded conductors.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite