In a blink of an eye, what is the prospect of the AI market? What new unicorns have been born? Let's take a look at the capital market's attention to AI. According to data from CB Insights, since 2020, the number of global AI financing transactions has continued to decline, from 506 in the first quarter to 458 in the second quarter. In comparison, before the epidemic hit, the number of transactions in the third quarter of 2019 was 660.

Looking at the data of the business cards of data service providers, China’s artificial intelligence field has completed a total of 371 financing transactions in 2019, with a financing amount of about 27.19 billion yuan. As of 2020, a total of 305 financings have been completed with a total amount of about 24.32 billion yuan. yuan.

Both global data and Chinese data are showing the decline in AI enthusiasm.

The wave behind pushes the wave forward, and the new AI unicorn enterprise makes its way

The editor searched for recent domestic AI financing transactions. Among them, there are not many corporate financing cases related to industrial AI, but we can see that a group of new unicorn companies are being tested by the market.

I don’t know if you find that from the perspective of technology applications, most industrial AI companies are focusing on the visual inspection market.

Traditional industrial inspections use manual inspections, but there are individual differences between individuals in the identification of defects, and long-term inspections can also cause fatigue of the staff, and many small defects in products cannot be efficiently identified. Moreover, with the disappearance of China's demographic dividend, many people are unwilling to engage in quality inspection, and companies are facing difficulties in recruiting workers. In this case, industrial quality inspection empowered by AI has attracted widespread attention.

Machine vision tools use machine learning algorithms, trained on a small number of image samples, and can find tiny defects on precision products with a resolution far beyond human vision. Product quality improvement can also be achieved through process optimization. Artificial intelligence performs perceptual analysis of key process step data, and implements optimization accordingly to improve yield. These applications can create considerable economic value for companies that produce expensive products and demand high product quality.

For example, a certain Chengdu factory adopted an automated optical inspection system to control PCB board defects. Due to the strict monitoring standards, 80% of the defects detected by the equipment were "false errors" after manual re-inspection. The combination of artificial intelligence and edge computing to identify "false errors" can reduce the cost of manual recheck by 75%, and at the same time achieve 100% "zero escape" of "true errors".

AI project implementation did not meet expectations

In the past AI, the capital market was quite active and many top players were born. However, as the market enters a cooling-off period, capital and society become more rational, and PPT players can only be a flash in the pan. Only the real implementation of AI projects is the way to lasting development.

Judging from the previous investment cases, the current AI investment market no longer pays attention to concepts and gimmicks, but real landing applications. What is needed is to help the industry quickly form applications for products to market.

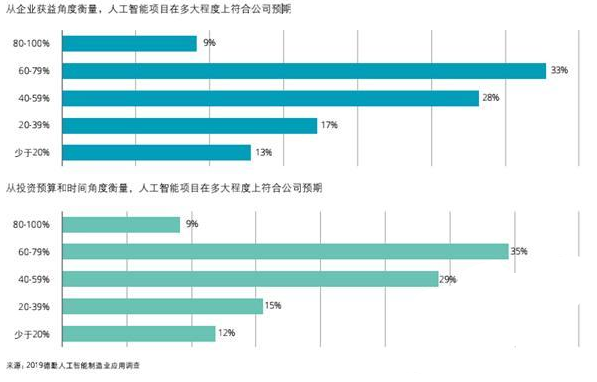

So, what about the implementation of AI projects today? According to the "Building All Things-Deloitte Artificial Intelligence Manufacturing Application Survey", there are not a few artificial intelligence projects implemented by Chinese manufacturing enterprises. However, no matter from the perspective of enterprise benefits or budget and time investment, the project is considered to reach 80%. -100% of the expected companies are only 9%. This means that 91% of artificial intelligence projects fail to meet business expectations.

Despite this, most companies still believe that in the near future, artificial intelligence will become an important factor in promoting enterprise production, and it will bring returns within 5 years.

Industrial AI has a long way to go

The foundation of artificial intelligence is human wisdom, which needs to be realized based on human experience and knowledge. Its application will be able to achieve a substantial increase in benefits, but the application of artificial intelligence in the industrial field is not as easy as in the consumer field.

First of all, data can only be brought through open interconnection, and only with this data can artificial intelligence be used to better serve customers. But the premise of all this is to ensure that the needs and wishes of customers are understood, such as what data customers are willing to open, but for the moment, for industrial enterprises, customers often worry that open data will reduce their competitiveness.

Secondly, the use of data is still limited. Many people do not know how to distinguish between good data, bad data, defective data, and invalid data. They cannot mark data correctly, and cannot determine the standard of data quality. Data is the foundation of AI, and AI can only play a role if you have enough data.

Furthermore, many companies lack artificial intelligence-related knowledge and professional technical talents, so they cannot successfully carry out the application of artificial intelligence technology. They believe that the implementation of AI must be an expert in the use of data science and software technology, and more concerns also come from the fact that the application of AI is not only complicated, but also time-consuming and expensive.

The editor believes that to some extent, AI is just one or a series of technologies. When an enterprise is clear about the problem it wants to solve, how to apply artificial intelligence to solve the problem, and apply artificial intelligence in the entire workflow, it can truly exert its value.

Although the large-scale implementation of AI in the industrial field is worth looking forward to, there are still many problems to be solved between ideals and reality. In the past, the AI industry has been rushing into the sand, some companies may flutter their wings, some companies may leave the market sadly, but this is not the end, and the landing of industrial AI will also be a protracted battle.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite