Wind turbines due to the operating environment or the quality of their own causes of fire, will cause speeding, down tower and other vicious accidents, if the fan is surrounded by grassland or forest areas may lead to grassland, forest fire, the consequences could be disastrous. Wind turbines are so crazy and appalling after the fire. In the event of fire, fire fighting will face many problems.

Analysis on the Causes of Frequent Fire in Wind Turbine

(A) high altitude is not easy to rescue

The main components of the wind turbine, such as the engine room and the leaves running at the height of seventy to eighty meters from the ground, the equivalent of 30 stories, usually when the fire is relatively large, the general fire truck water pressure is difficult to reach such a high degree of fire Can only "forget the fire".

(B) the field is not easy to rescue

Wind farms are usually far away from the city, fire engines are difficult to arrive in time. Offshore wind turbine fire rescue is far away, a fire, often only allowed to burn.

Fire rescue difficulties is on the one hand, the fan's own fire hazard is another aspect

(3) field lightning

Fan units are located in the field where the wind speed is relatively large, such as ridge, open plains, etc., and these places is precisely vulnerable to lightning areas. Lightning energy size is difficult to predict, and the wind turbine lightning protection design system is in accordance with a certain standard design, there is capacity limit. When a lightning protection system defect or an actual lightning strike exceeds the design criteria, a fire occurs.

(D) fan design and manufacturing defects

The design of the fan is designed to meet the characteristics of the local operating environment, but some fans are defective in manufacturing. Such as in the seaside or sea to run the fan, you need to consider the impact of salt spray on the corrosion of electrical equipment, and some fans are not installed humid air filtration system, resulting in cabin cabinets and other high-voltage transformers and other equipment, corrosion, resulting in foggy corona discharge phenomenon, and finally Causing a short-circuit fire. Some fan gear box oil serious, there will be some oil on the floor, encountered an emergency brake, the brake disc spilled Mars will cause a fire. Some wind turbine lightning protection performance is poor, not correctly in accordance with the requirements of the lightning protection partition design of the corresponding lightning protection measures, and some poor manufacturing quality grounding is not properly installed, or the wind farm itself, long-term corrosion of the grounding grid lead to ground performance Drop and so on. These factors will be in operation due to their own (electrical protection level down) or the outside world (lightning) caused by fire.

(5) the service is not in place

As the wind power in recent years, soaring capacity, personnel training can not keep up, many maintenance personnel at work without fan awareness. Wind turbine maintenance personnel due to work carelessly, sometimes after the end of the maintenance in the cabin to leave contaminated cotton yarn, or gear box oil is not timely scrub clean. When the unit is in an emergency brake, the brakes will wipe off the Mars, splashing on the cotton wire may lead to cotton wire lead to fire.

Due to the above problems, the wind turbine must be equipped with automatic detection, automatic fire fighting function and stable performance of the fire device. However, due to the special operating environment of the wind turbine, the network of water-based, storage pressure heptafluoropropane and other generations of fire extinguishing devices have failed to achieve the desired fire function, and there are the following problems: the domestic wind power industry has been copying the urban building pipe network fire control system,

(6) easy to accidentally trigger

When the wind farm lightning, the system prone to false trigger, a number of wind farms have occurred too many units or even the whole field of false triggering, to the operation of wind turbines bring a lot of trouble.

(7) the system is easy to fail

For the active sensor (smoke sense, warm sense), the power supply system has always been one of the risks of the fire, the power supply system failure caused the sensor failure, the system became deaf blind, can not effectively trigger the fire extinguishing device. Often active sensor low temperature performance is poor, at low temperature when the function failure, in the event of fire, can not effectively trigger.

(8) pressure vessels bring risks

Some systems use pressure vessels up to 15MPa, does not meet the "protected area is not allowed to store the pressure vessel" requirement. Wind farms day and night or winter and summer temperature difference, resulting in the loss of extinguishing media, if not timely replenishment, the system will greatly reduce the efficiency of fire extinguishing.

(9) maintenance work complicated

Active sensors usually require sensor testing every two years, regular cleaning of dust; pressure vessels need to check the pressure regularly, the cabin inside the need to arrange complex pipe network. This gives the daily operation and maintenance work to bring an additional burden.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite

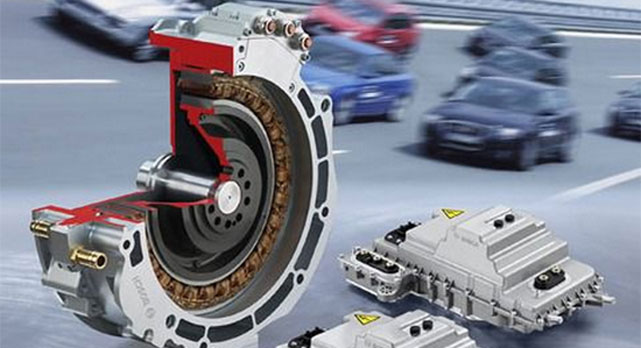

![[New energy] - electric motor principle](/upload/image/20170519/20170519090819_74516.jpg)