Each system has a system of construction standards for each system, whether it is dry construction, or do the management staff to understand the basic construction process, improve the quality of the project, the best project

First, the construction methods and process standards

The construction methods and process standards of each system implement the following standard specifications and requirements:

"Lightning and grounding installation process standards" (322-1998)

"Trunk wiring installation process standards" (313-1998)

"Pipe laying process standards" (305-1998)

"Civil closed circuit monitoring television system engineering technical specifications" (GB50198-94);

"Construction electrical installation sub-project construction technology standards"; (533-1996);

"High-rise civil design fire safety norms" (GB50045-95)

"GB65100-86" 30MHz-1GHz audio and television signal cable distribution system

"GB11318-89" 30MHz-1GHz cable and cable signal distribution system

"GB50200-94" cable TV system engineering technical specifications

Technical specification for "GY / T106-92" cable television broadcasting system

"GBJ" civil construction cable television system engineering technical specifications

The main construction process: cable laying, equipment installation, system commissioning.

2.1 construction points

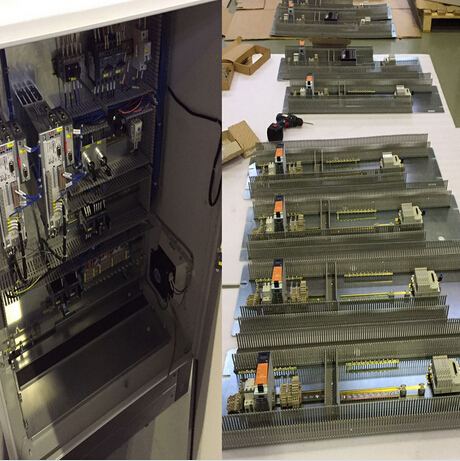

Pin positioning: According to the design to determine the installation location, from the beginning to the terminal (after the trunk line) to find a good horizontal or vertical line, calculate the line to the line and cable according to determine the good construction map, where to identify and punch How many holes are used to determine the direction and number of horizontal and vertical cables and the size of the trunking.

Requires the use of materials should be straight, no significant distortion. The distance between the fixed fulcrum should not be greater than 1.0-1.5mm, in the access junction box, box, cabinet, turn, and so on, Corner and T-junction within the three ends of 500 should be fixed support points, support, plastic bolts specifications should not be less than 8mm, self-tapping screws 4mm * 30mm.

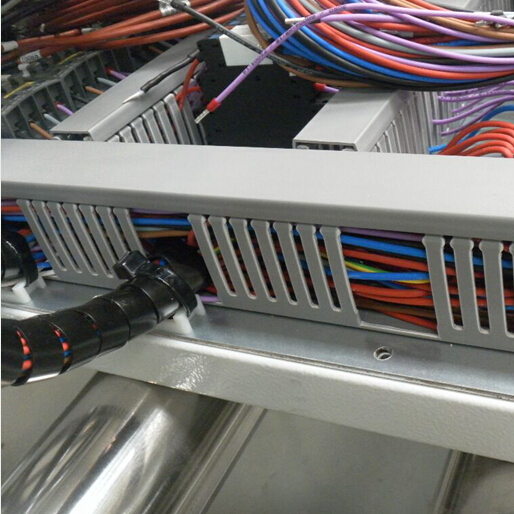

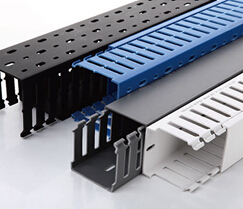

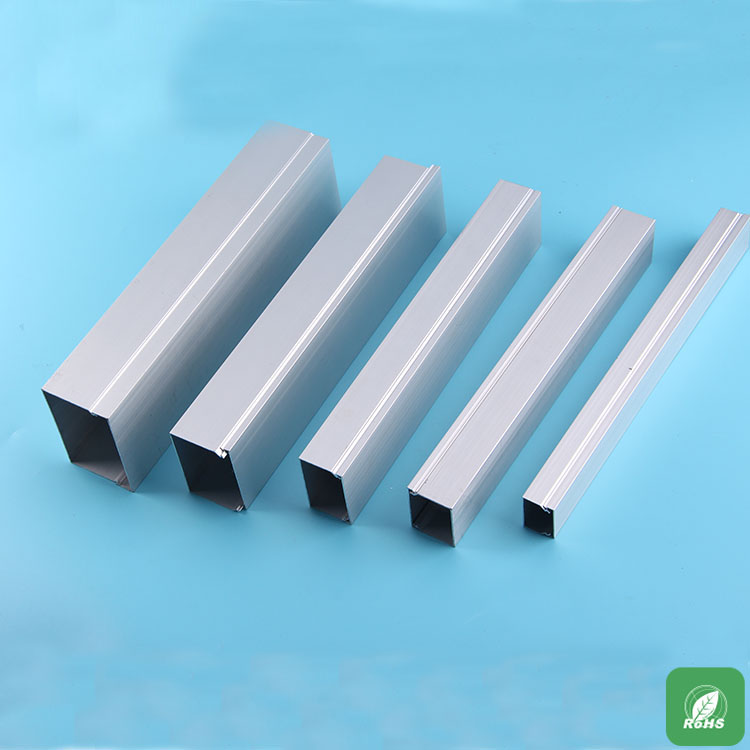

Trunking installation requirements: trunking should be flat, no distortion, no glitches inside the wall, all kinds of accessories complete; trunking interface should be smooth, seams close straight, slotted should be installed after the flat, And all the corners of the trunking shall be connected and connected to each other so as to be a continuous conductor and be fully grounded. The installation of the trunking shall be in accordance with the Code for Fire Protection of High-rise Civil Building Design (GB50045-95) Sector regulations;

Trunk wiring requirements: trunking wiring should be removed before the dirt; cable layout should check the model specifications, procedures, routing and location consistent with the design requirements. The sum of the cross-sectional areas of the conductors including the insulation in the same trunking shall not exceed 40% of the internal cross-sectional area; the laying of the cables shall be straight and shall not cause twisting, circular motion and so on, And the damage; the cable should be labeled at both ends of the cloth to indicate the start and end positions, the label should be written clearly, correct and correct; power lines, signal cables, twisted cables, cables and other weak buildings The cables of the system should be disassembled. The minimum clearance between the cables should meet the design requirements; cable layout should be redundant. In the interchanges, the equipment between the twisted cable reserved and degrees, usually 3 to 6 meters; work area of 0.3 to 0.6 meters; cable at the equipment side of the length of the general reservation is 5 to 10 meters; special requirements should be designed Required length of reservation;

Cable laying: In the process of traction, the hanging cable fulcrum spacing should not be greater than 1m; laying cable traction force, should be less than 80% of the allowable tension cable, the cable maximum traction should not exceed the maximum allowable cable The tension. When laying the cable in the way of towing, the main traction force should be added to the reinforcing core of the cable. When the cables in the cable tray are laid vertically, at the upper end of the cable and at every 1.5m interval, they should be fixed on the bracket of the bridge. , The direct part of the interval from the application of 3-5m fixed point. In the distance from the beginning of the cable, the tail, turn the center point of 300-500mm at the fixed point; slot cable should be straight, as far as possible without cross, the cable should not overflow trough, the cable into the trunking , The corner should be tied to fixed. The vertical trough laying cable shall be secured to the cable bracket at intervals of 1.5 m to prevent the cable from falling down; the cables shall be banded when laying cables in horizontal, vertical and vertical trunking. 4 pairs of twisted pair cable to 24 for the beam, 25 pairs or more backbone twisted pair cable, cable and other credit cable should be based on the type of cable, cable diameter, the number of cable bundles for the bundle. Lashing spacing should not be greater than 1.5m, buckle spacing should be uniform, elastic to adapt; in the shaft with the use of clear wiring trough laying the cable, and should meet the above requirements.

2.2 equipment installation

① Equipment inspection before installation

Before the construction of the installation of the equipment should be installed appearance, model specifications, quantity, signs, labels, product certification, certificate of origin, brochures, technical documents to test whether the equipment selection of factory original products, equipment performance has reached the design requirements and national standards Provisions;

② Installation:

A. The installation location should meet the design requirements, easy to install and construction;

B. Installation should be strong, should be designed according to the earthquake requirements of the construction;

D. The surface should be complete, no damage, the screw is strong, the surface convexity per square meter should be less than 1mm; the surface deviation should be less than 1mm;

E. The connector and equipment in the machine are reliable;

F. Machine wiring should meet the design requirements, terminal signs should be complete, to maintain good;

G. Taiwan wiring equipment, grounding, protective grounding, wire cross-section, color should meet the design requirements;

H. All cabinets should be grounded and connected to the ground terminal of the building.

2.3 debugging

A. Test the cable with the line tool

B. Cable debugging is good, the best mark

C. Cable commissioning record table

Third, the construction schedule and schedule arrangements

Preparation principles: adhere to the principle of unified plan, do a good job of comprehensive balance, realistic, leaving room; adhere to the construction process, pay attention to the continuity of construction and balance.

Preparation basis: the requirements of the project contract model; construction plans budget and construction organization plan; within the enterprise human resources, funds and other guarantee conditions.

Construction schedule preparation: the overall planning of the project, the main use of sub-process construction law, according to the construction of a phased approach.

Construction preparation phase

Engineering field survey; deepening the design program; technical program demonstration; construction technology to the end; materials and equipment procurement, testing;

Cable laying:

① cable material into the report ② cable laying ③ cable detection, recording and acceptance

Equipment construction phase; equipment entry inspection; equipment installation: ① weak equipment installation ② room equipment installation project completion phase

System commissioning; completion of data processing and delivery; system self-test and rectification; system training; completion of acceptance, delivery

Summarize the following points

1, the cable must be marked 2, pressure line must be responsible for serious 3, the cable must be finishing 4, a good record

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite