Electronic technology era, life makes it difficult for people to leave electrical and electronic products, and the most used in electronic products is the terminal harness. Harness in our eyes seems simple, but in the production process of the terminal harness manufacturers every step can not be ignored, and the terminal harness design to be reasonable, the process to regulate the requirements and so on. What exactly is the process it!

The first step in production is the opening of the terminal harness

Open line technology should strive to be accurate, can not be any error, for example: open line size is short, thus affecting the entire production schedule. Therefore, before carrying out the open-line process, you must carefully study the wiring harness drawings, according to the requirements of the drawings, a reasonable determination of wire opening size, stripping size, and then create open-line instructions, the production process card.

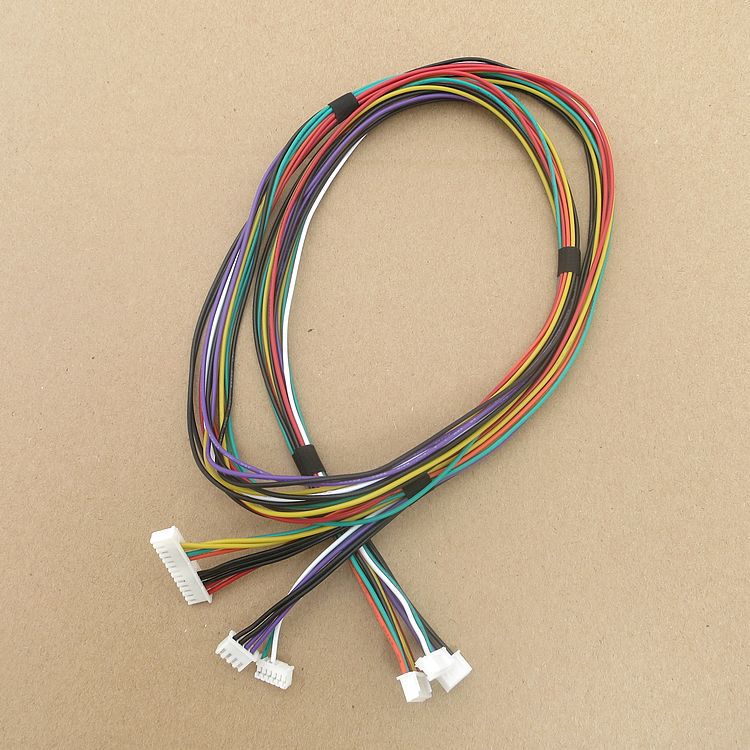

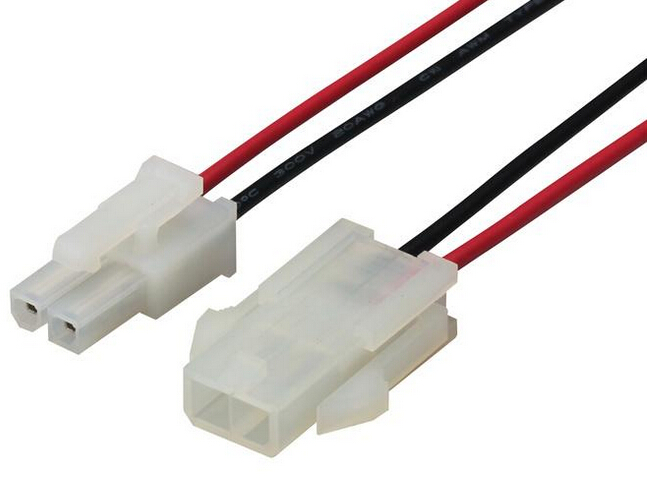

The second step of the production process is the crimping process of the terminal harness

According to the type of drawings to determine the type of crimp parameters, production of crimp operation manual, for special requirements need to be marked on the process file and train operators. For example: Some wires need to be passed through the sheath before crimping, it needs to be pre-installed wire and then return from the pre-installed station and then crimp; puncture pressure crimp used special crimping tools, which Crimping methods have good electrical contact properties.

The third step is the production of terminal wiring harness assembly process

The ability to tailor the assembly platen, design tooling, and material box design to the harness product development department, and assign the numbering of all the mounting sheaths and accessories to the material box for greater assembly efficiency. Preparation of the various station assembly content and requirements, balance the entire assembly station to prevent a bit workload is too large, pulling down the entire assembly line speed. To achieve the station balance, the process staff must be familiar with each operation and fieldwork man hours, adjust the assembly process at any time. All in all, harness manufacturers only pay attention to every step of harness production process, to be able to ensure the quality of the harness.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite