(1) The protection structure should be designed when the high-voltage cable has sharp edges or via holes, and the heat source should be kept away from or kept at a sufficient distance.

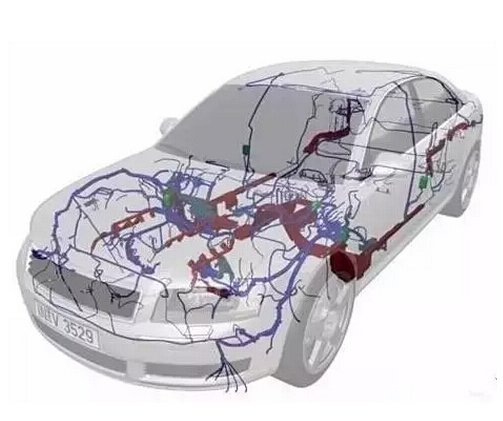

(2) The high voltage cable has a large outer diameter. To avoid stress concentration, the minimum bending radius of the wire harness is usually 3 to 5 times larger than the wire diameter, and the cable also has a large mass. In order to distribute the load rationally, it is necessary to support and fix the wire harness. Usually, the distance between the fixed points of the cable is ≤300 mm, and the distance between the fixed point and the connector is ≤120 mm to withstand the

weight and vibration load of the wire harness. Fixed devices often use special mesh straps and insulating material brackets.

(3) For connector fittings assembled inside components, fasteners of the correct specifications need to be selected to ensure that the connectors are in contact with the electrical plates and that the product is tightened and tightened.

(4) The motor wiring harness should take into account the influence of component movement and vibration. The reasonable design of the wiring harness size must not only have enough length distribution stress, but also avoid excessive cable length due to long-distance distribution. For cables with large displacement, additional buffers are needed. With the fixed structure of the guiding function, the cable maintains a reasonable distance from other components during movement. For the parts that generate noise during the movement, sponge, flannel, tape, and other components should be added to avoid noise.

(5) The connectors shall be placed as far as possible in the cab or inside the electrical compartment to avoid the erosion of rainwater and dust. The wiring harness arranged in the chassis shall be designed with a shielding structure to avoid the adverse influence of vehicle wading and stones splashing; Try to avoid vertical layout to avoid the accumulation of water and dust.

(6) Harness layout should consider electromagnetic interference factors. Avoid 90 when wiring. The folding line can reduce the high-frequency noise emission of the line; for the high and low voltage wiring harness, especially the signal wiring harness, it must be arranged separately to avoid the mutual interference caused by the cross arrangement of the cables.

(7) The appearance of the exposed high voltage harness should also consider the aesthetics of the layout. The direction of the harness should be consistent with the direction of the attachment, and the oblique direction should be avoided; the cables of the cabin should be placed below the body structure or components and inside; as for the cable For many locations, special harness guards should be developed for shielding.

(8) The arrangement of high-voltage wiring harnesses should have a suitable space for installation and maintenance. The connectors at the same location should use different specifications and positioning structures to prevent misinstallation; connectors should be connected as far as possible to ensure one-hand operation, connectors. The end harness should be set a reasonable length to facilitate the assembly and disassembly of the connector.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite