We all know that in the field of new energy vehicle charging piles, wire harnesses can generally be divided into two categories:

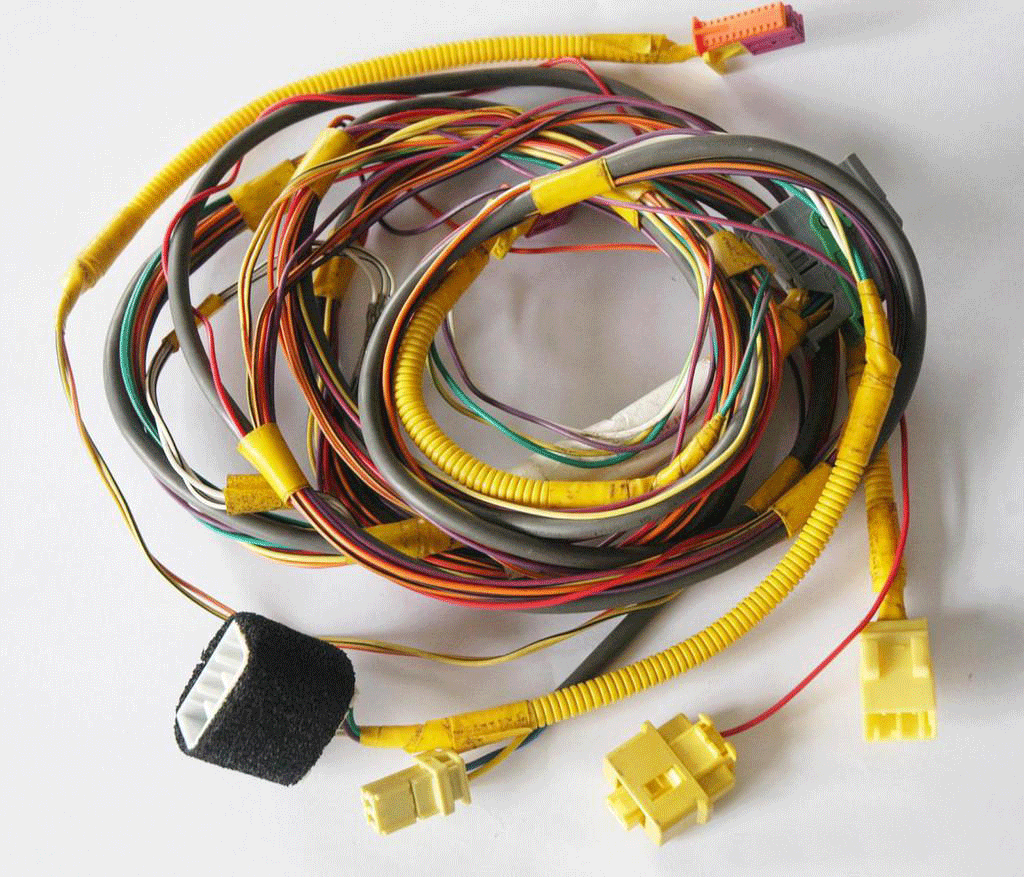

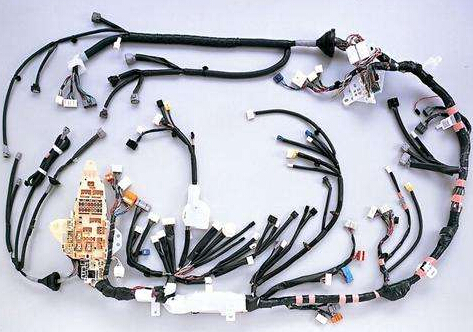

1. The wire harness represented by the interior of an electric vehicle can be categorized into a category by including high voltage harnesses and low voltage harnesses.

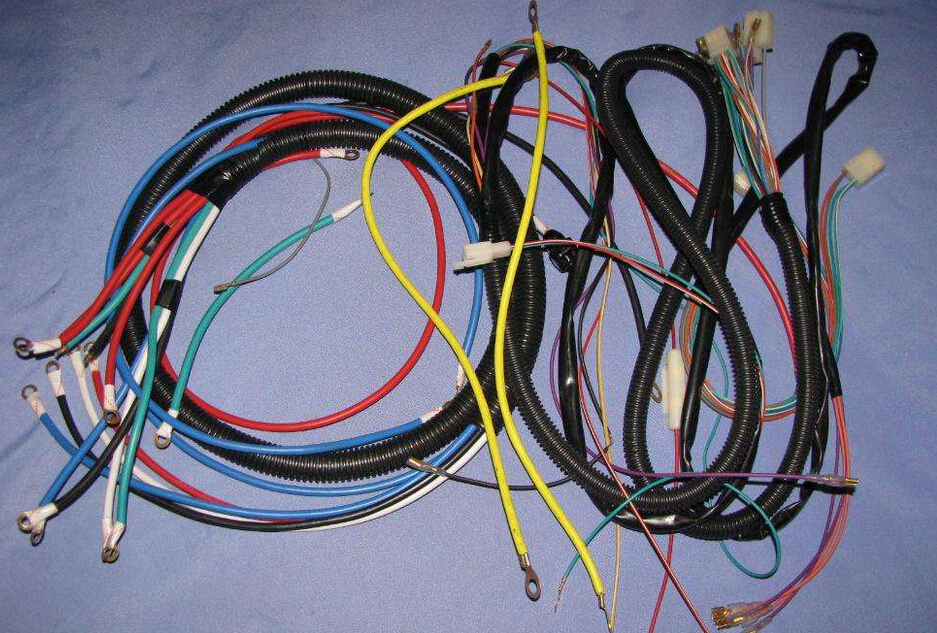

2. The charging pile harness can be classified into another category

What's the difference between them?

First, laying different

The wiring harness generally refers to the wiring of the harness after reaching the power distribution box and reaching the electrical equipment or another distribution box. The wiring harness is changed according to the nature of different environmental conditions.

The automobile high-tension wire harness is fixedly installed, but the static bending radius of individual points is very small; the charging wire harness belongs to mobile laying, and the dynamic bending radius is small.

Second, different heat resistance

The higher the heat resistance of automobile high-voltage harness, the better, the higher the heat resistance, the greater the carrying capacity, so the start is 125 degrees, the high 180 degrees (silicone rubber), 200 degrees (fluororubber); charging harness is generally exposed to the outside, Don't be too hot. Do not exceed 70 degrees. Otherwise it will cause burns.

Fourth, different protection measures

The necessary protective measures must be taken around the high-voltage wiring harness of the car; the charging harness has no protective measures and must withstand various impacts and UV exposure.

Fifth, the physical performance requirements are different

The automobile high-voltage harness needs to meet the requirements of the car's wear; the charging harness must meet the rolling resistance requirements of the moving harness.

Sixth, different chemical resistance

The automobile high-voltage wire harness must withstand various liquids that the car can contact; the charging harness must withstand various liquids in the living environment outside the automobile.

Seven, different size requirements

Automotive high-voltage wiring harness is limited by space, strict with the size requirements, and the smaller the size, the better; the charging harness is not limited in size and can be made thicker and bigger.

Eight, different color requirements

It is internationally stipulated that the color of automobile high voltage harnesses is orange; there is no requirement for the charging harness color.

Nine, the number of wire harness core is different

Automotive high-voltage wiring harnesses are usually single-core for ease of laying. Charging wiring harness is usually a multi-core integrated wiring harness, which includes high-voltage main line, ground line, low-voltage signal line, and even communication double-effect line (CAN). ).

X. Different international standards

International standards for automobile lines are established by the ISO organization; international standards for charging lines are established by the IEC organization.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite