Recently, the Ministry of Industry and Information Technology has publicly solicited opinions on the “Requirements for the Examination of Entry Permits for Road Motor Vehicle Production Enterprises (Draft for Solicitation of Comments)” and “Requirements for the Examination of Entry Permitting of Products for Road Motor Vehicles (Draft for Comment)”, and proposed that enterprises should establish waste power batteries. Stable recovery channels ensure safe recycling of waste power batteries.

In the scrapping and recycling process of the power battery, both the use of the ladder and the recycling of raw materials require the support of the recycling subject. However, the current situation is not ideal. So why is power battery recycling difficult?

Recycling main body absent

In accordance with the characteristics of the power battery, follow the principle of recycling, China currently advocates the principle of decommissioning the power battery first and then scrapping and recycling, and requires the vehicle company as the main body of power battery recovery, to assume the responsibility of battery recovery. However, since most vehicle companies are only "assembly plants" for electric vehicles, batteries are provided by specialized battery companies. This brings about the phenomenon of the coexistence of three main types of power battery recycling: The first category is the entire vehicle company; The second category is battery production enterprises; the third category is power battery scrap recycling enterprises and raw material companies.

"According to regulations, auto companies should bear the responsibility of the main recovery, but car prices are not a panacea." Cui Dongshu, secretary-general of the National Passenger Vehicle Market Information Association, said that to a certain extent, car companies are more like electric car "assembly plant." During the warranty period, it is responsible for the normal use of batteries, production and supply, secondary use and recycling, but it is battery company expertise. "I think that whoever sells batteries and who is responsible for the batteries should at least cooperate with each other. Unfortunately, battery companies are often excluded from the recycling system and the responsibility is not yet clear."

Recovery technology bottleneck to be broken

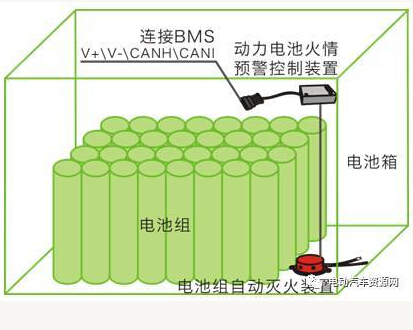

Due to its large size and complex composition, the recycling and reuse of power batteries are faced with many limitations and higher technical barriers.

Because the types, specifications, and processes of decommissioned batteries are not different from each other, there are diversity in the form of series parallel connection, application models, use time, and operating conditions, resulting in complicated dismantling. At the same time, there is no uniform standard for power batteries in China, and it is difficult to concentrate on the use of large areas.

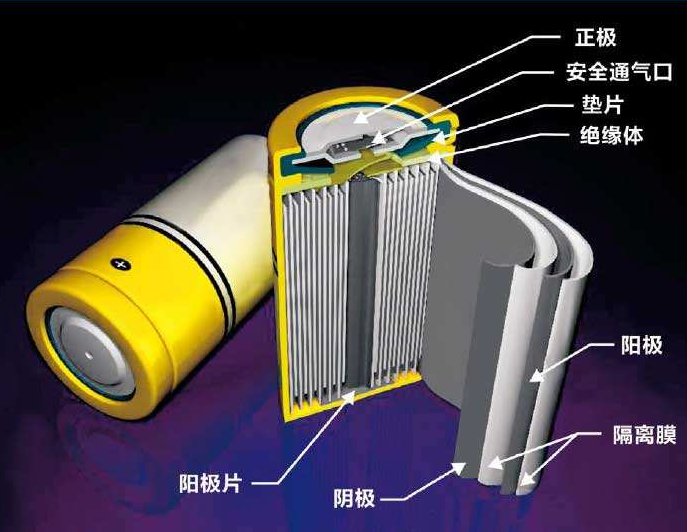

From the point of view of recycling batteries alone, even if it is a lithium battery, the positive electrode material is also various, and there are mainly lithium cobalt oxide, lithium manganese oxide, lithium nickel-cobalt-manganese oxide, and lithium iron phosphate. Leaching with acid and alkali solution, and then through a variety of chemical processes, the extraction of metal oxides. However, the extraction conditions of the components of these oxides are different, and the mixture is more difficult.

Uncertain recovery model

Despite the difficult start, the outlook is generally optimistic about the industry. On the whole, the current large-scale "retirement tide" of power batteries has not arrived yet, and it is difficult to form large-scale effects for the dismantling and recovery of power batteries.

For example, some car companies have chosen to cooperate with other companies to jointly promote the recovery of domestic power batteries and other related matters. Sixteen vehicle and battery companies, including Changan, BYD, and Yinlong New Energy, have reached cooperation with China Tower Corporation, a major power battery recycler, to solve issues such as the recycling of retired power batteries.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite