Ten reasons for motor vibration

1. Rotor, coupler, coupling, transmission wheel (brake wheel) caused by imbalance.

2. Core bracket loose, oblique keys, pin failure loose, the rotor is not tightly bound to cause some unbalanced rotation.

3. linkage part of the shaft is not right, the center line does not coincide, centering is not correct. This failure is mainly due to the installation process, the poor, improper installation caused.

4. Link part of the center line in the cold state is coincident, but after a period of time due to the rotor fulcrum, foundation and other deformation, the center line has been destroyed, resulting in vibration.

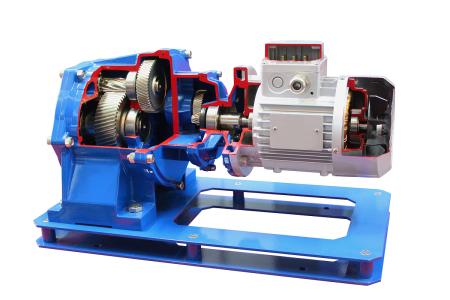

5. Gear associated with the motor, the coupling is faulty, gear bite bad, bad teeth wear, bad wheel lubrication, coupling skew, dislocation, tooth coupling tooth profile, pitch is not, the gap Large or serious wear, will cause a certain vibration.

6. The structure of the motor itself defects, journal oval, shaft bending, shaft and the gap between the bearing is too large or too small, bearing, base plate, a part of the foundation and the entire motor installation foundation stiffness is not enough.

7. Installation problems, the motor and the base plate between the fixed is not strong, the foot bolt loose, loose between the bearing and the base plate and so on.

8. The gap between the shaft and the bearing is too large or too small can not only cause vibration can also make the bearing lubrication and temperature anomalies.

9. Motor drag the load conduction vibration, such as the motor drag the fan, pump vibration, causing the motor vibration.

10. AC motor stator wiring error, winding type asynchronous motor rotor winding short circuit, synchronous motor excitation winding inter-turn short circuit, synchronous motor excitation coil connection error, cage type asynchronous motor rotor broken bar, rotor core deformation caused by the rotor air gap is not Are, resulting in uneven air gap flux caused by vibration.

The vibration of the motor

Motor vibration, bearing insulation and bearing life will be shortened, affecting the normal lubrication of sliding bearings, vibration force to promote the expansion of the gap, so that external dust and moisture intrusion, resulting in lower insulation resistance and leakage current increases, and even the formation of insulation breakdown And so on. In addition, the motor vibration, and easy to cooler water pipe crack, welding point vibration, and will cause damage to the load machinery, reduce the accuracy of the workpiece, will cause all the vibration of the mechanical part of the fatigue, Or broken, the motor will cause the carbon brush and slip ring of abnormal wear and tear, and even a serious brush fire and burn the collector ring insulation, the motor will produce a lot of noise, this situation is generally in the DC motor also occur.

Causes of vibration and typical cases

There are three main causes of vibration: electromagnetic aspects of the reasons; mechanical reasons; mechanical and electrical mixing reasons.

1 Electromagnetic aspects of the cause

1. Power: three-phase voltage is not balanced, three-phase motor running.

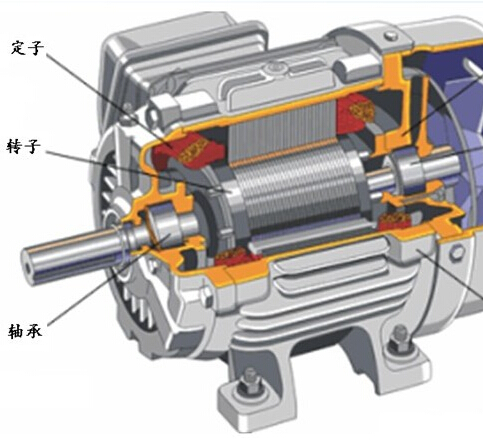

2. stator: stator core variable oval, eccentric, loose; stator winding disconnection, grounding breakdown, turn short circuit, wiring error, stator three-phase current imbalance.

For example: boiler room sealed fan motor repair before the stator core has a red powder, suspected stator core loose phenomenon, but does not belong to the standard overhaul range of the project, so untreated, overhaul after the test machine when the harsh screams, Replacement of a stator after troubleshooting.

3. rotor failure: rotor core variable oval, eccentric, loose. Rotor cage and end ring welding, rotor cage break, winding error, brush contact bad and so on.

Example: the sleeper section of the toothless saw motor running found that the motor stator current swing back and forth, the motor vibration gradually increased, according to the phenomenon of motor rotor cage to determine the possibility of welding and fracture, the motor disintegration and found that the rotor cage has 7 broken , Serious two sides and the end of the ring has been completely broken, such as the discovery is not timely may cause the stator burns the occurrence of bad accidents.

2 mechanical reasons

1. The motor itself:

Rotor unbalance, shaft bending, slip ring deformation, fixed, rotor air gap uneven, fixed, the rotor magnetic center is inconsistent, bearing failure, poor foundation installation, mechanical strength is not enough, resonance, loose feet screw, motor fan damage.

Typical case: the factory condensate pump motor after the replacement of the bearing, the motor shaking increased, and turn, the stator has a slight sweeping signs, carefully check and found that the motor rotor lift height is not right, turn, stator magnetic center is not on, re-adjust Thrust head screw cap, the motor vibration fault elimination. Cross-line hanging ring Yang motor after the maintenance of vibration has been too large, and there are signs of gradual increase in the motor when the hook is found when the motor vibration is still large, and the axis has a large string of movement, disintegration found that the rotor core loose , The rotor balance is also a problem, replace the spare rotor after the failure to eliminate the original rotor to repair the factory.

2. With the coupling with: the coupling damage, poor coupling coupling, coupling center to find the center are not allowed, load mechanical imbalance, system resonance and so on.

❶ Associated part of the shaft is not aligned, the center line does not coincide, centering is not correct. This failure is mainly due to the installation process, the poor, improper installation caused. There is also a situation, that is, some of the linkage part of the center line in the cold state is coincident, but after a period of time due to the rotor fulcrum, foundation and other deformation, the center line has been destroyed, resulting in vibration.

For example: a, circulating pump motor, running vibration has been too large, the motor check without any problems, no load is also normal, the pump class that the motor is running normally, and finally check out the motor to find the center difference too much, the pump class from the new to find Positive, motor vibration elimination.

B, the boiler room induced draft fan in the replacement of the pulley, the motor test run when the vibration at the same time the motor three-phase current increases, check all the circuit and electrical components no problem finally found the pulley failed, after the replacement of motor vibration elimination, while the motor three The current is back to normal.

3 Cause of motor mixing

1. Motor vibration is often uneven air gap, causing unilateral electromagnetic tension, and unilateral electromagnetic tension and further increase the air gap, this mechanical and electrical hybrid performance for the motor vibration.

2. Motor axial string, due to the gravity or installation of the rotor itself and the magnetic center of the wrong, caused by the electromagnetic tension, resulting in axial rotation of the motor, causing the motor vibration increases, serious cases of shaft grinding Wag, the bearing temperature Rapidly rising.

❷ Gear associated with the motor, the coupling is faulty. This failure is mainly manifested as bad gear teeth, bad teeth wear, bad wheel lubrication, coupling skew, dislocation, tooth coupling tooth profile, pitch is not right, the gap is too large or serious wear and tear, will cause a certain vibration.

The defects of the motor itself and the installation of the problem. This fault is mainly manifested as the journal oval, the shaft bending, the shaft and the gap between the bearing is too large or too small, bearing, base plate, a part of the foundation and the entire motor installation foundation stiffness is not enough, the motor and the base plate between the fixed Not loose, the foot bolt loose, loose between the bearing and the base plate and so on. And the gap between the shaft and the bearing is too large or too small can not only cause vibration can also make the bearing lubrication and temperature anomalies.

Driving vibration of the motor. For example: Turbine generator steam turbine vibration, motor drag fan, pump vibration, causing motor vibration.

How to find the cause of vibration

To eliminate the motor vibration, first of all to find out the reasons for the vibration, only to find the cause of vibration in order to take targeted measures to eliminate motor vibration.

1. When the motor is not stopped, use the vibration table to check the vibration of each part. For the vibration part, the vibration value is measured in three directions according to the vertical horizontal axis. If the screw is loose or the bearing end screw is loose, Direct tightening, fastening after measuring the size of its vibration to observe whether there is to eliminate or reduce, followed by the three-phase voltage to check whether the balance of power, three-phase fuse is a blown phenomenon, the motor single-phase operation can not only cause vibration, But also make the motor temperature rise rapidly to observe whether the ammeter pointer swing back and forth, the rotor break when the current swing phenomenon, and finally check the motor three-phase current is balanced, found the problem in time to contact the operator to stop the motor running, so as not to burn the motor damage.

2. If the motor after the surface treatment, the motor vibration is not resolved, then continue to disconnect the power, unlock the coupling, so that the motor connected with the load mechanical separation, single-turn motor, if the motor itself does not vibrate, Is the coupling does not find or load the machine caused by the motor if the vibration, then the motor itself has a problem, you can also take the power to distinguish between electrical reasons, or mechanical reasons, when the power outage moment, the motor immediately does not vibrate or Vibration is reduced, then the description of electrical reasons, otherwise it is a mechanical failure.

For maintenance reasons

1. Maintenance of electrical causes:

First, the stator is measured three-phase DC resistance is balanced, such as imbalance, then the stator wire welding parts of the phenomenon of open welding, breaking the winding phase to find the other winding whether there is inter-turn short circuit phenomenon, such as fault can be from the insulation The surface to see the scorched traces, or with the instrument to measure the stator winding, to confirm the short circuit between the turn, the motor windings off the assembly line.

For example: pump motor, running motor not only vibration large bearing temperature is also high overhaul test found that the motor DC resistance failure, the motor stator winding has welding phenomenon, with the exclusion method to find the fault to eliminate the motor running everything is normal.

2. Maintenance of mechanical reasons:

Check the air gap is uniform, if the measured value exceeded, re-adjust the air gap. Check the bearing, measure the bearing clearance, such as the failure to replace the new bearings, check the core deformation and loosening of the situation, loose core can be used epoxy adhesive bonding, check the shaft, the bending of the shaft to repair welding or straight , And then do the balance test on the rotor. When the motor is overhauled during the trial operation, the motor is not only vibrating, but also the bearing temperature is exceeded, and the fault is still solved after several days of continuous processing. I team members to help deal with the discovery, the motor air gap is very large, tile level is also unqualified, the cause of failure to find, re-adjust the gap after the Ministry of motor test a success.

3. Load the mechanical part of the inspection is normal, the motor itself is no problem, causing the fault is caused by the connection part, then check the motor's basic level, tilt, strength, center to find out whether the correct coupling is damaged, Whether the motor shaft extension degree meets the requirements and so on.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite

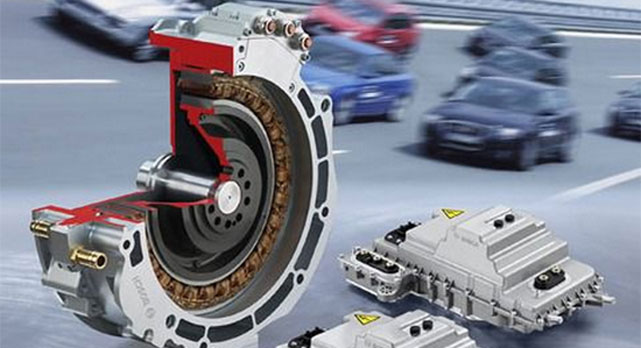

![[New energy] - electric motor principle](/upload/image/20170519/20170519090819_74516.jpg)