Discussion on the Causes of Burning of Motor Terminal Blocks

2. The motor coil and the outlet terminal are not fastened, which can also cause heat.

3. Short circuit burnout due to insufficient creepage distance between terminals due to dust and oil.

4. Short circuit burnout due to insufficient creepage distance between terminals due to dust and oil.

5. The surface of the terminal block and the terminal block may be oxidized, resulting in an increase in the resistance value of the contact portion and more heat generation, thereby causing a malfunction.

6. Humidity causes the insulation resistance to become small, causing a short circuit.

7. Short circuit occurs when the creepage distance is less than or greater than the corresponding voltage

Generally speaking, the three-phase terminal of the motor is manufactured by the manufacturer at the factory when the distance between them is set according to the regulations. The insulation distance should meet the requirements. If the terminal frame is intact, it will not be arc due to insufficient distance. Causes a short circuit. To analyze this fault, under the premise that the motor junction box remains intact, there are two problems to be considered. First, when the terminal is burned, the coil of the motor is burnt out, and all the coils of the motor are intact, then the problem is all In terms of the terminal block, the second is that the motor coil is damaged when the terminal block is burned, and it is another matter.

If the motor is put into use after being stopped for a period of time, the possibility of oxidation due to moisture and wiring is relatively large, and burning due to heat generated by poor contact. If the motor runs frequently, the terminal block burns out during operation. It should be judged that the terminal stud is loose, and there is a temperature accumulation for a period of time. When the humidity in the air rises, the surface of the terminal is oxidized, which will also cause The contact resistance increases, and after reaching a certain level, the phenomenon deteriorates faster and faster. In the case of a complete junction box, it is generally difficult to find, and this failure eventually occurs. Therefore, the general operational requirements for electrical equipment are also regulated. Regular inspections and inspections are good methods for reducing failures. There are opportunities for downtime. Opening the box inspection can reveal early signs of some failures.

Related articles

-

One minute a comprehensive understanding of new energy vehicles motor

Now the development of electric vehicles faster and faster, and electric vehicle motor research and development, but also aroused our concern, but really understand the electric car motor is very few people. Xiao Bian for everyone collecting information, as we have a good talk about electric car motor knowledge. Let us explore the next high-tech car heart!

-

Introduction to Electric Motors

Refers to the law of electromagnetic induction in accordance with the conversion or transmission of electrical energy of an electromagnetic device. Motor (also known as motor), in the circuit with the letter "M" (old standard with "D") said. Its main role is to generate drive torque, as a power source for electric vehicles.

-

The use of robots to expand the size of the terminal block or benefit

The use of robots to expand the size of the terminal block or benefit

-

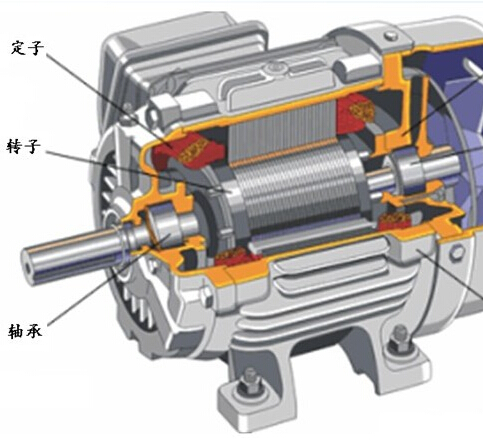

A variety of motor principles to understand the more profound

Through the intuitive motor animation, to understand the working principle of the motor!A motor (commonly known as"motor") refers to an electromagnetic device that converts or transmits electricity ac

-

![[New energy] - electric motor principle](/upload/image/20170519/20170519090819_74516.jpg)

[New energy] - electric motor principle

[New energy] electric vehicle motor principle1, what is the motor?A: The motor is to convert the battery power into mechanical energy, driving the electric car wheel rotating parts.2, what is the stat

-

There are several ways to brake the servo motor?

Servo motor braking method is divided into the following three categories:1, electromagnetic brake① electromagnetic brake is through the mechanical device to lock the motor shaft.② electromagnetic bra

-

Brief introduction of motorcycle harness

Motorcycle harness is a motorcycle on the network of nerve, wiring harness design is reasonable, reliable enough quality, directly related to the safety of vehicles and personal, must fully understand

-

Analysis on the Causes of Frequent Fire in Wind Turbine

Wind turbines due to the operating environment or the quality of their own causes of fire, will cause speeding, down tower and other vicious accidents, if the fan is surrounded by grassland or forest

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite