If you plan to buy a car, what is the most important indicator? It is estimated that 100% of people will say safety and price. So, what kind of indicators will you pay attention to while ensuring safety and reasonable price? It is estimated that this is the best choice which one to choose, so the current car design is increasingly pursuing fashion sense. LED lighting can bring a more intuitive and cool experience to the car, and the energy saving effect is better, so the application is more and more widely, including car headlights, car taillights, window lighting, functional lighting, advanced lighting and so on. According to Strategy Analytics, security and branding are the two main factors driving LED acceptance in the car's headlight platform, which currently has an annual growth rate of 30%.

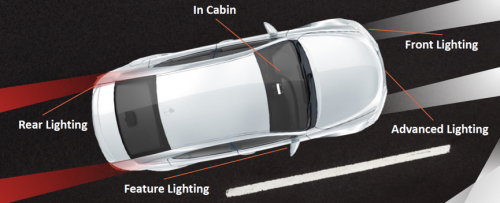

Figure 1 LED lighting in automotive applications

However, LED lighting designers are also faced with many challenges, such as: space, cost and design complexity requirements, need to reduce the overall BOM cost; high-power applications require more efficient, need to equip efficient devices; design needs to be flexible Sexuality needs to make full use of the platform design to solve the reusability problem; to suppress EMI as much as possible to ensure system security. In response to these problems, Maxim has introduced a new solution, Tamer Kira, Director of Business Management, Automotive Products Division, said, "Our chip integration is getting higher and higher, which can help users reduce BOM cost; high-efficiency devices for synchronous rectification can help Users reduce power consumption; multi-topology devices are easy to use and increase design flexibility; integrated spread-spectrum features reduce transient noise to suppress EMI."

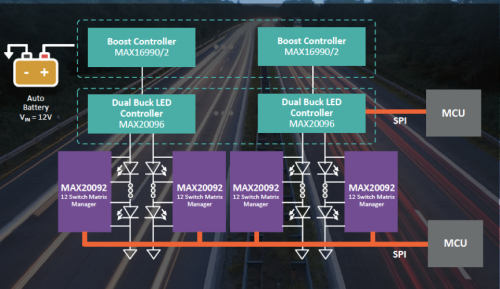

Since multiple cars are required in a car, OEMs are introducing advanced security management for LED and matrix lighting designs. Maxim's MAX20092 is a 12-channel switch matrix manager, Tamer Kira said, "This device enables high-performance LED array headlights and adaptive beam conditioning to meet higher current device requirements while reducing solution size and flexibility. The on-resistance of the matrix switch is the lowest in the industry, and the IC minimizes the heating of the LED array illumination, which is 65% lower than the closest competing solution."

Figure 2 LED lighting application based on MAX20096 and MAX20092

Highly integrated, single-chip step-up buck for seamless switching

Integrating multiple functions is a major trend in future chip design. The advantage of integration is that a single chip can perform multiple functions, and engineers do not need to add other circuits to reduce BOM cost. In the automotive system, there must be a buck-boost function. The traditional method is to complete the boost chip and the buck chip separately, and Maxim integrates these two topologies on one chip.

Of course, this kind of integration scheme can also be implemented by some companies. The difference is that their scheme needs to go through an intermediate state when switching between boost and buck, which will cause a large voltage drop, and Maxim's solution can be upgraded. The switching between voltage and buck is seamless, so the output voltage is more stable. Tamer Kira uses MAX20092 as an example to explain, “When the number of LEDs is relatively large, the required voltage is relatively high, and a boosting scheme can be used. When the voltage is very low, a step-down scheme can be adopted. The MAX20092 can support 1-4 strings of LEDs, and Buck can be used. /Bootst buck-boost meets different LED quantity configurations for greater flexibility and reusability."

Narrow frequency fast response for lower EMI

During the driving process, whether the lights can accurately and timely signal the car is safe for the owner. Therefore, real-time monitoring of the lamp failure is an important part of ensuring driving safety. MAX20092 can be widely used in matrix LED lighting management modules such as headlights and turn signals. As shown in Figure 2, the battery voltage of the car is 12V volts, which is increased to 60V by MAX16990/2, and then stepped down by MAX20096 to provide suitable LED matrix. Voltage. The MAX20092 features advanced fault protection and open, short, and wire break LED detection management to ensure safe driving.

If you want to manage multiple LED lights, you need to control the MCU one by one through the SPI bus. If you switch frequently, the bus pressure will increase. The MAX20092 integrates 12-switch matrix. You can control the LEDs connected to the switch through the 12-way switch. And each switch can be controlled separately. Tamer Kira introduced the advantage of separate management, "When the system switches from lighting 1 LED to lighting 12 LEDs, it can be controlled by MAX20092. If lighting an LED requires 4V, lighting 12 LEDs is required. Raised to 48V, the MAX20096's new control architecture can respond quickly, such a fast response switching frequency change is very narrow, the switching frequency of the same kind of products from 4V to 48V rotary output varies greatly, it is difficult to filter, so EMI is very large, we need to respond quickly, and we need to ensure that the switching frequency range is very narrow during this response time, so as to achieve lower EMI interference, the MAX20096's slew rate control can reduce EMI and noise. In addition, MAX20092 also adopts RDS_ON as low as 70 milliohms supports up to 1.5A of LED current drive for low power consumption and high efficiency."

Multiple devices work in parallel for large pixel array control

A MAX20092 can control 12 LEDs. If multiple groups are needed, can multiple MAX20092s be connected in parallel? According to Tamer Kira, "The MAX20092 can connect up to 27 MAX20092 devices in parallel, eliminating the need for daisy-chaining and managing large pixel arrays of up to 324 LEDs; allowing designers to configure 1 (string) x 12 serial switches for each IC, 2 (string) x 6 series switches, and 4 (string) x 3 series switches, you can see that multiple sets of LED control can be implemented on the same SPI bus, OME manufacturers can flexibly increase or decrease the number of modules to meet Differentiated needs of different car manufacturers."

In addition, Maxim also introduced the MAX20096 and MAX20097 dual-channel, synchronous buck high-brightness LED controllers, working in conjunction with the MAX20092 to help designers improve the transient response of LED lighting. The MAX20096 and MAX20097 enable ultra-fast transient response with near-fixed frequency with Maxim's unique average current mode control, minimizing EMI and supporting reliable, high-performance designs.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite